Water in the house all year round: how to insulate a well for the winter

Content

Why insulate a well

As soon as the thermometer crosses the zero mark at night, there is an immediate risk of water freezing in the water pipes. Not only will it not be possible to use the water, there is a high probability of pipe destruction, which can be eliminated only after the onset of heat or in emergency mode. If there is no need to use the well in the cold season, then we drain the water from the system, and all the frosts do not care. If there is a need for water all year round, you need to think about how the well will be prepared for winter.

Video "How to insulate a well or well"

From this video you will learn how to properly insulate a well or a well for the winter.

Warming methods

So that in the cold season the house does not remain without water, you need to think about how to insulate the tap in the yard for the winter, the upper head of the well and the pipe through which water is supplied. Such insulation can be a caisson device, a pipe-in-pipe method or a heating cable. It is important to choose the right insulation material and its design features. The use of modern materials and technologies will make it possible to prepare the cottage for the use of water all year round.

Heat insulating materials

Depending on the climatic conditions of the location of the country house, a selection of materials is made that will allow you to freely use the column or street tap during the cold season. For a mild and warm climate, it will be enough to make a box slightly larger in size for the head of the well and fill it with natural insulation, which we can easily find at our summer cottage:

- straw;

- sawdust;

- dry leaves;

- high-moor peat.

They can also be used to insulate a tap in the yard and pipes that supply water to the house. But this is possible only in the southern regions, where winter temperatures do not drop below 10-12 ° C below zero.

For other regions, it will be correct to use modern industrial insulation based on polyurethane foam and mineral base:

- polystyrene and polystyrene;

- polyurethane foam;

- basalt fiber;

- mineral wool;

- foam insulation.

These heat-resistant materials are easy to use and install. They can be easily processed with a cutting tool. At the same time, they retain all their thermal insulation properties. These materials are placed inside a volume that requires insulation - be it a caisson or a separately made box for a crane, which is located in the yard.

When using thermal insulation materials, it is important to know their properties. Mineral wool or fiberglass absorbs moisture. This will not allow it to be used with high humidity or a close location of groundwater. Glass wool easily deforms even under light loads. Thermal insulation from such material requires the creation of additional protective covers and contours.

Polystyrene and polystyrene are moisture resistant and easy to process. Such material is convenient for creating complex contours of insulation. But he needs protection from rodents.Polyurethane foam retains heat and does not allow moisture to pass through. Basalt fiber is produced with a thin layer of aluminum foil for waterproofing. It is a convenient but very expensive material.

Foam heaters are made specifically for water supply and heating of various diameters in the form of pipes that are put on the required section of the supplied communications. This method of insulation is relevant when laying pipes through the air outdoors or indoors. In the ground, the foam rubber will be deformed under the weight of the soil and will not be able to fulfill its functional purpose.

A convenient but expensive material is polyurethane foam. This foam should be used to insulate pipes after laying by spraying. It is important to know how to properly lay pipes for such insulation.

There is another method of pipe insulation - by applying thermal paint, which has heat-resistant properties. It is used to insulate pipes in hard-to-reach places.

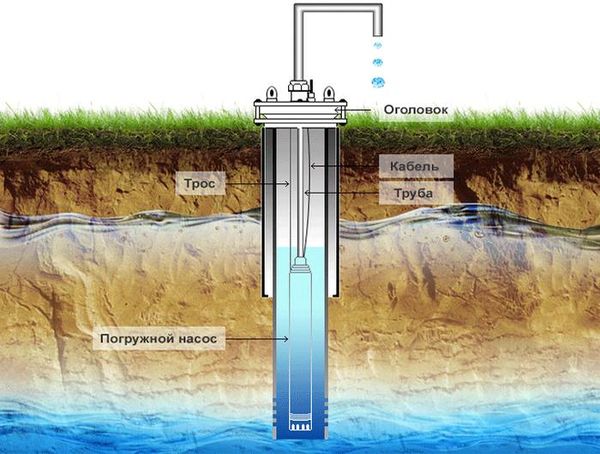

Caisson

First of all, let's figure out what a caisson is. This is a special tool of cylindrical or square shape, which is designed to pull the casing out of the well. It is usually located below the freezing point of the soil, but this depends on the well design. The direct purpose of the caisson is to preserve the pumping equipment located at the wellhead.

The caisson is needed in order to provide convenient access to the water intake fittings when repair and maintenance is required. A hydraulic accumulator, filters, a pumping station - all this is located inside the caisson.

Regardless of the depth at which the equipment of the pumping station is installed, the head of the well is above the earth's surface. The head material is not heat resistant. This means that at negative temperatures there is a possibility of water freezing in the well equipment.

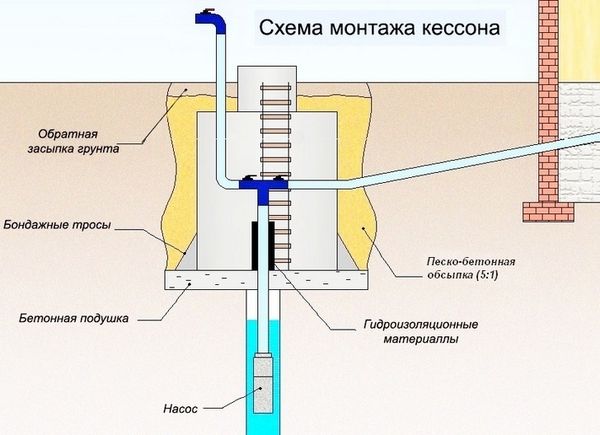

Regardless of the shape and material (except plastic) from which the caisson is made, you need to insulate its inner surface. If the body is sealed and the inner part is protected from moisture, then the applied insulation is protected from moisture. If the rodents do not get to the inside of the caisson, then its surfaces are insulated with foam or expanded polystyrene.

Regardless of the shape of the inner surface, all its parts are covered with a layer of thermal insulation. The use of polystyrene will require a large thickness of insulation, at winter temperatures below 25 ° C - 10 cm. Expanded polystyrene has the best heat resistance. Its thickness for the same climate will be 5–7 cm.

The body of the plastic caisson may not withstand the low temperatures of a cold winter. Therefore, such a body is insulated from the outside. For this, an additional box is made, which has large dimensions relative to the body of the caisson. The inner surface of the box is insulated with foam.

The plastic caisson can be insulated from the outside. Given the high risk of damage to the insulation by rodents, use polyurethane foam or other insulation that protects against pests and moisture.

External insulation will save the internal space. This is an important factor for the maintenance and repair of equipment inside. All insulation work does not require high qualifications and is done by hand.

If the lower part of the caisson is not very deep, and there is a possibility of freezing of the insulated body, then a heating element is installed. Usually, a low-power tubular electric heater (TEN) or a small piece of heating cable is used. Such elements are usually supplemented with a temperature sensor that monitors the internal temperature and, if necessary, turns on heating.

Heating cable

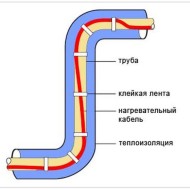

Well insulation with heat-resistant materials is referred to as passive protection. But there are other, more modern methods.The use of a heating cable is an active method and often becomes the only correct solution when preparing a water supply system for winter in the country. This will be especially true when the well is rarely used in the cold season.

The heating cable is laid in two ways:

- inside the water pipe;

- outside the heated pipe.

The cable, which is used for indoor installation, complies with sanitary standards, is non-toxic and meets higher electrical safety requirements relative to other heating or simple wires. The connection of such a cable to the water supply is carried out through a special tee, which must be built into the existing network. Then measure the length of the pipe that will be heated by this cable. Measure this size on the cable and feed it through the tee into the pipe.

This heating method has a high efficiency and is very efficient. The big disadvantage is that curved sections of the network cannot be traversed with this cable.

Another method of heating with a cable has a lower efficiency and its installation is more laborious. To heat the water supply with an external cable, wrap the pipes with foil. Then, using aluminum thermal tape, they attach the cable to the pipe.

Typically two heating cables are used for heating. They are placed along the pipe or laid in a spiral around the pipeline. The more turns of the spiral there are in the same sections of the pipe, the better the heating will be. With a high risk of pipes freezing, external cables are laid in a combined method: two shared wires are supplemented with several spiral ones.

To ensure economical operation of the system when performing such insulation, a thermostat is installed with an internal or external heating cable. The sensor of this regulator is mounted directly on the pipe and the switch-on and switch-off temperature is set in the range of 3-5 ° C. This setting will avoid frostbite of the pipes and, in the absence of frost, will allow the system to remain off.

The considered method is convenient, but the cost of heating cables, especially internal ones, is very high. In addition, in winter, not all summer cottages are constantly supplied with electricity. Therefore, the relevance of this method is considered individually.

Insulation of the liner to the house

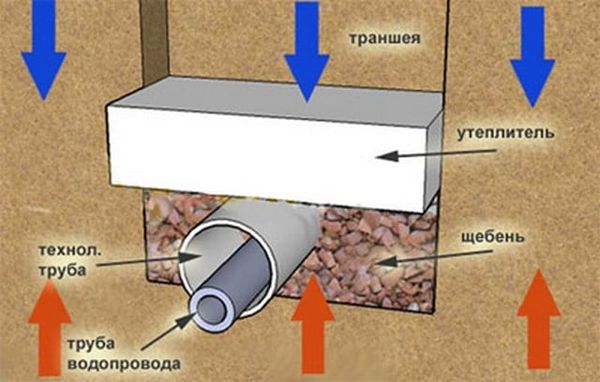

If it is necessary to use water in the winter in the house, it is important at the stage of laying the supply pipe to carry out all the necessary measures to prepare the system for winter operation.

If the pipe was laid and inserted into the house at a depth of more than one and a half meters, then there is no need for insulation.

A country house is often connected to the water supply using a shallow laying of pipes, well above the freezing level of the soil. Often there are options for external connection by air or directly on the ground. In these situations, insulation is indispensable.

For pipes, special heaters of various diameters are made from industrial materials. The use of mineral wool, basalt wool or foam rubber is important for air pipeline laying. For laying underground, these heaters must be covered with an additional casing to prevent the insulation from shrinking.

For pipe insulation, the use of polystyrene is relevant. But in the places of supply to the well and to the house, this insulation is protected from a possible attack by rodents.

The use of mineral fiber insulation, foam rubber and foam will be appropriate when laying pipes inside unheated rooms, including basements. To protect against rodents and the ingress of moisture, which is often formed in basements, the insulation is wrapped with a waterproofing material, possibly even roofing material.

The most reliable, albeit expensive, is polyurethane foam insulation of pipes. It is most convenient to use foam, covering the surface of the pipes, it will be possible to avoid freezing.It is important to lay the pipe on an expanded clay pillow before covering it with foam. This will allow the insulation to completely cover the outer surface of the pipe.

Having studied the intricacies of preparing a well for winter, you can safely get to work.