We build a polycarbonate winter greenhouse with heating

Content

Heating types

All this led to a great demand for polycarbonate greenhouses, which, in addition to purely utilitarian use, have also become elements of landscape design for the territory of many suburban areas. Moreover, such a structure can be bought ready-made, made to order or assembled without any problems with your own hands.

Greenhouses are quite suitable for active operation in winter, but this will require the arrangement of heating and lighting systems. If the structure is only warmed up, this will allow the greenhouse season to start a month earlier than usual.

For heating greenhouses in winter and early spring, it is possible to use various types of heating, some of them are easy to do with your own hands, while others will require careful calculations and the involvement of specialists for installation.

The simplest is biological heating or the so-called warm beds. In this case, thermal energy is released as a result of the decomposition of organic matter as a result of the vital activity of microorganisms. The biofuel is horse manure or compost on its basis, which is placed under the soil layer. The heat from the organic layer warms up the plant root system

In winter, air heating can be used by moving streams of heated air through the greenhouse. It is carried out by means of electric or gas heaters. Electric heat guns are fairly powerful portable fans. In gas heaters, heating is carried out by means of heating pads dispersed over the area of the greenhouse or heated air is distributed using a system of air ducts.

A variant of the winter heating system by heating the air is the use of convectors. Only in this case there is no forced propagation of warm air, and its heating occurs due to convective flows, which contributes to, although longer, but uniform heating. Such devices are predominantly electrical, but they can also be gas.

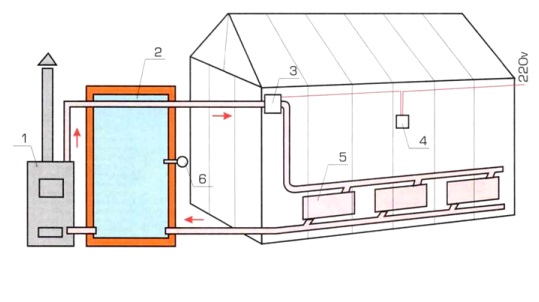

Water heating of the greenhouse in winter is based on a pipe system installed under the soil layer and a heating boiler operating on one of the types of fuel: solid fuel, liquid fuel, electric or gas. Which of these types to install for heating greenhouses in winter sometimes depends on the availability of a particular fuel in the region.

Resistive cable heating is quite efficient and popular with greenhouse owners. This electrical system uses two types of heat sources - a separate heating cable or ready-made heating mats. The cable is laid not only under the soil, but can also be laid in the walls of the greenhouse, providing effective heating even in severe winter cold.

Heating a winter greenhouse with infrared radiation sources is currently considered the most progressive method from the point of view of plant ecology.

Video "Heating a winter greenhouse"

Can I use IR

The effect of infrared heating sources is in its physical essence similar to heating by the sun's rays. IR radiation does not heat the air, but the opaque objects that absorb it. Then, from the heated layer of soil, plant leaves, frame and other elements, heat is transferred to the air due to convection. The winter greenhouse warms up in a similar way to a summer bed heated by the sun.

That is, the use of infrared heaters in greenhouses is not only possible, but also the closest to the natural way of heating. At the same time, the soil warms up to a depth of 7 centimeters, which creates the most camphor conditions for the root system of plants for nutrition and active growth. At a time when the soil warms up to +28 ˚С, the air in the greenhouse heats up only to +22 ˚С. In addition, the air does not dry out, there are no drafts and harmful emissions from the combustible fuel. Thus, the IR heating system creates the most optimal conditions for development in the winter greenhouse.

Types of IR heating

Modern infrared heaters are light and elegant. It will not be difficult to mount such heating in a greenhouse with your own hands. Their main elements are a ceramic emitter and a steel reflector polished to a mirror finish. According to their design features, they can be divided into two main types: case and film or tape.

The first ones are mobile and can be fixed both on the walls and on the ceiling, lowering them to the required height. More modern body-based infrared heaters no longer have a flat, but a spherical emitting surface, due to which their scattering angle reaches 120 degrees, which significantly increases the uniformity of heating.

Film IR heaters are permanently mounted in the ceiling. However, the loss of mobility in them is compensated by greater energy savings and higher uniformity of soil heating in a winter greenhouse.

These heaters mainly use electricity as a source of energy. But they can also be gas or liquid fuel. This allows you to choose the most optimal option in terms of cost savings during operation and to ensure uninterrupted operation in winter cold.

Do it yourself

A winter greenhouse must have efficient, reliable and economical heating. If you install it yourself, you need to take into account the peculiarities of the climate, the advantages and disadvantages of various types of heating, as well as the ability to independently make the correct installation and configuration. What will be the heating system for a polycarbonate greenhouse depends on the specific situation.

When using biological heating, in addition to heating the root system, the plants also receive vitamin supplementation, and the outgoing vapors help to moisten the soil. Such heating is quite simple to equip in a greenhouse with your own hands and does not require constant monitoring. However, the heat generated by this will not be enough even in small winter frosts.

Air heating rather quickly warms up the air in the greenhouse, which is important in case of a sharp cold snap in winter. The equipment can be equipped with thermostats, which will automatically maintain the required temperature. At the same time, the use of gas for a polycarbonate greenhouse can be quite profitable financially.

However, rapid heating has a downside - the greenhouse also cools down quickly when the heat supply is interrupted. Therefore, a winter power outage or gas interruption will lead to the death of plants. In addition, the air dries up and the soil does not warm up.If the electric guns are placed in the greenhouse and connected with their own hands is not a problem, then in order to make a gas system, especially when connecting not cylinder gas, but main gas, you will need to involve a specialist.

The convection heating system of the greenhouse is easy to equip with your own hands. In addition, the electronic control of the equipment makes it autonomous and automatic. Its disadvantages are the same as those of the air system - there is no heating of the soil and rapid cooling when the power is turned off, which is dangerous in winter frosts.

The water heating system heats both the soil and the air in the greenhouse. In addition, the heated water after turning off the boiler will give off heat to the environment for a long time. That is, in the event of an emergency shutdown, the winter cold will not immediately reach the plants in the greenhouse. But with such heating, the soil is very dry, which requires timely watering. In addition, not everyone can calculate and make such a system with their own hands without attracting a specialist for installation.

A winter greenhouse with a cable heating system allows you to create a favorable microclimate for plants, since in this case the soil and air are simultaneously warmed up. In addition, the use of special sensors and controllers makes it easy to program it for an effective heating level both in winter and during spring warming.

However, such heating will require calculations and some electrical knowledge for correct and safe installation. Also, in the event of a power outage, winter frosts can destroy all plantings, but the connection of an electric generator will be the salvation of the situation.

With infrared heating, a winter greenhouse provides plants with the most comfortable growing conditions. The use of electronic control makes it possible to integrate it with the “smart home” system, which makes it possible to regulate the microclimate in different parts of the greenhouse, depending on the surrounding conditions. It is not difficult to make such a system in a greenhouse with your own hands, and at the same time you can ensure uninterrupted operation in the event of a disconnection of the main power source.

Video "Automatic greenhouses made of polycarbonate"

Some greenhouses are far from homemade equipment, and have their own lighting, irrigation and heating systems. How it works, you will learn from the video.