How to build a greenhouse thermos with your own hands

Content

Peculiarities

One of the most famous breeders Anatoly Patiy designed and patented such greenhouses. Such a greenhouse has the main feature that, in comparison with other greenhouses, it makes it possible to grow heat-loving and light-loving crops throughout the year. Moreover, the costs of maintaining the desired temperature and creating suitable conditions in winter are practically minimal.

This is due to the thermal effect that is formed due to the special design of the greenhouse, much like a thermos. That is why the greenhouses of Patiya received such an original name.

People who use these greenhouses for the constant cultivation of crops note that they are quite economical and efficient in operation. The main disadvantage is the significant costs and efforts in their construction. But with high-quality construction, such greenhouses will fully pay for themselves. They are durable, and with their year-round operation and a competent approach, you can get very good profits from growing crops. It should be noted that these greenhouses allow you to grow many exotic heat-loving fruits, vegetables and flowers.

It is very important to note that a properly designed thermos greenhouse allows you to maintain a positive air temperature in cold seasons without any heating. This is achieved by providing unobstructed access to sunlight and isolating the interior space not only from the effects of the air environment, but also from cold soil. When building a greenhouse, first of all, it is necessary to take into account the following features:

- the structure should be buried in the ground to the depth of soil freezing with full plating of the foundation with heat-insulating material;

- the structure should be located in length from east to west so that the penetration of daylight is maximum;

- the presence of external thermal insulation of the above-ground parts on the drilled side of the greenhouse is mandatory;

- the aboveground part should be sheathed with a translucent double covering;

- there must be a reflective coating on the inner insulated side;

- for upholstery of the sides of the garden, it is necessary to use an opaque black film, which, absorbing the sun's rays, will give off heat to the soil of the greenhouse.

As a result, taking into account the above aspects, it is possible to build a structure that will serve as a solar collector that converts light into heat.

Advantages

According to Anatoly Patiya, the inventor of the greenhouse himself, the main emphasis he placed on when developing a thermos greenhouse was its year-round use with minimal human intervention in the process of maintenance and care. As you can see in practice, the creator managed to achieve this goal. In addition, the high cost of energy resources prompted him to create such a greenhouse structure. So, the project he created consumes more than 15 times less heat than other types of greenhouses.

Now, several years after the implementation of this promising project, not only a well-known breeder, but also many gardeners were able to see the advantages of a thermos greenhouse.

The main advantages include:

- High productivity. In such a greenhouse, the percentage of the yield obtained is 2-3 times higher than in conventional greenhouses.

- Long operational periods. Such greenhouses are quite reliable, since they are constructed from durable materials using modern technologies and can last for more than a dozen years without major repairs;

- Due to the good permeability of sunlight (about 91%) and the creation of a greenhouse climate for the corresponding plant species, greenhouse conditions are as close as possible to natural;

- High thermal insulation indicators, indicating the reliability of keeping heat inside the structure and saving heat and energy resources;

- Even distribution of heat and light by using polycarbonate;

- High strength of the frame and foundation to the effects of adverse external factors of nature. Resistant to temperature extremes, precipitation and strong winds;

- The ability to grow a large number of various crops in the greenhouse, including exotic ones.

Also, a significant advantage of this type of greenhouse is the ability to transform them from an ordinary greenhouse into a thermos greenhouse.

Video "Construction of a greenhouse-thermos in winter"

The author of this video shares his own technology for constructing a thermos greenhouse.

Mounting

The construction of a greenhouse is a rather complicated matter, especially if it is the construction of a "thermos". It is important to initially understand that you will have to spend a lot of effort, time and money to build this structure. Some gardeners entrust this work to specialists, but most still prefer to do this work on their own, since they believe that a built-in thermos greenhouse with their own hands is much more reliable and financially much cheaper.

Before starting construction work, it is necessary to clear the area where the trench will be dug in the future. Its width should be no more than 5 m (to maintain the thermos effect), the length should be at your discretion, and the depth should be from 1, 2 to 2.5 m, depending on the region where the construction is carried out, since the level of soil freezing differs in different territories ...

After the excavation has been dug, the strip foundation is laid to the entire height of the trench. It can be erected with concrete blocks or poured with concrete into an iron formwork. In any case, it is important to touch up the interblock seams so that cold and moisture do not seep into the greenhouse.

After the foundation is formed, it should settle for 1 month. At this time, it can be insulated from the outside with expanded polystyrene. After laying the foundation and its shrinkage, the walls of the greenhouse are erected. Their height should be between 0.75-1 meters.

Walls are erected from a thermoblock, brick or any other material used for construction. When laying the last row, provide for several embedded fasteners on which the roof frame will be fastened.

The greenhouse roof should be lightweight. Its frame is assembled from wood or metal profiles. According to his technology, Anatoly Patiy proposes the creation of a gable roof, but other breeders argue that in this case it is a gable roof that is more effective, since the sun's rays at a right angle increase the illumination area.

But at the same time, one nuance should be taken into account: when forming a pitched roof, the northern wall should be higher than the southern one. And the slope of the roof is steeper, so that when snow hits, it does not linger and fall, not having time to freeze.

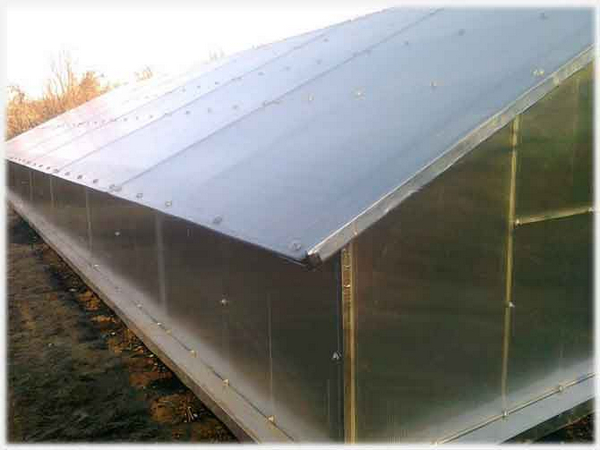

The most suitable material for roofing is cellular polycarbonate.It combines all the necessary qualities: light transmission, lightness, ease of attachment, resistance to significant loads.

After carrying out external work, you should proceed to internal. The first step is to seal the greenhouse, carefully sealing all the cracks with polyurethane foam. Next, the most important part is creating conditions for the thermal effect. For this, all walls are covered with thermal insulation materials from the inside. It is noteworthy that a foil-clad thermal insulation film is attached to the northern wall. In addition to the fact that it will retain heat, it will also be a reflector of the sun's rays that penetrate the greenhouse through the polycarbonate.

After sheathing the walls, in conclusion, it is necessary to finish the roof from the inside, hemming it with translucent materials. In this case, it is not necessary to use polycarbonate; it is enough to do with a greenhouse film. But the plus of polycarbonate is that there is no need for its frequent replacement, compared to the film, which needs to be changed every three years, due to the loss of its light transmittance.

The final stage in the arrangement of the greenhouse is the equipment of the beds and the embankment of soil mixtures. If necessary, a water supply should be provided that will automatically supply water, or install a pair of large barrels, painted black for better heating of the container.

There are no restrictions for the internal arrangement of the greenhouse, the main thing is that, with multiple proactive improvements, the microclimate does not deteriorate and the thermal effect remains at the desired level.

Video "About the greenhouse-thermos"

The creator of the thermos greenhouse Anatoly Patiy talks about his invention.