What is the best thickness of polycarbonate for the greenhouse

Content

Useful qualities

Many gardeners do not think about what material they need to create a greenhouse and immediately choose cellular polycarbonate. This product has certain features that make it a leader in greenhouse construction.

Cellular polycarbonate is a material made from granules of colorless hard polymer plastic. Such plastic is produced using the extrusion method. This method involves melting plastic granules with further extrusion through a special shape called a die. It is because of the use of this method of production that this product has a number of features. Thanks to these features, many gardeners choose it.

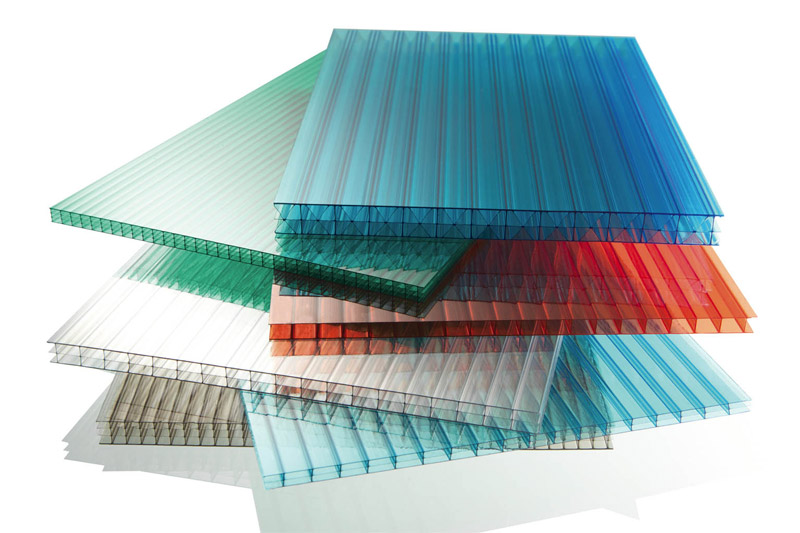

Cellular polycarbonate looks like a sheet with a cellular structure. This product can consist of two or more layers, which are interconnected by stiffening ribs oriented in the direction of the length of the sheet. A feature of this structure of the product is the presence of high thermal insulation properties, as well as increased strength. Therefore, honeycomb and other types of such products are often used for wall and ceiling cladding in greenhouses of various designs.

Gardeners and gardeners began to use honeycomb and other types of polycarbonate for decorating a greenhouse due to the following useful qualities of this material:

- low thermal conductivity, due to which such sheets retain heat best of all;

- high resistance of the product to ultraviolet radiation;

- high indicators of light transmission. The transparency in this case is 90%;

- high impact resistance. When broken, the sheets do not form splinters. Therefore, they are better than glass for construction purposes;

- fire resistance. Polycarbonate is practically non-flammable. It is also prone to self-extinguishing;

- high resistance when exposed to many chemicals on the surface;

- durability. The service period is over 20 years;

- such products can be used in a fairly wide temperature range: from -40 to +1200 C. Thanks to this, such a product is perfect for a winter greenhouse;

- it is possible to bend sheets in a cold state. At the same time, they retain their plasticity. Therefore, no other analogue can cope with a winter greenhouse better than polycarbonate.

Another positive quality of this product is its low weight. Polycarbonate should be chosen in a situation where the construction is planned with an unreinforced frame and without a foundation (for example, for a pyramid greenhouse).

Thanks to such useful qualities, polycarbonate is used in various spheres of human activity (industry, agriculture and construction). In agriculture, it is better to choose it for construction:

- greenhouses;

- winter greenhouse;

- winter garden.

At the same time, what type of prefabricated structure a greenhouse or a greenhouse will have will not affect the operational time. The material under any climatic conditions will be able to efficiently and fully perform the functions assigned to it.

It is worth noting that depending on what type of polycarbonate you have chosen, the above parameters may vary within a certain range. For the construction of a greenhouse, it is best to use a honeycomb type of product.

Video "How the material behaves in winter"

At what thickness to stop

Polycarbonate sheets can be produced in different thicknesses (from 4 mm to 16 mm). Therefore, the question naturally arises as to what thickness the products are best used for the construction of greenhouses and other agricultural buildings.

Today, sheets with a thickness of 4 mm are in the greatest demand. You need to choose this parameter when assembling a light greenhouse structure. But many experts, when asked “what thickness should you buy polycarbonate products for greenhouses,” argue that it is better to use a 6 mm material. This parameter will prevent damage to the skin during hail. Therefore, if hail is a common phenomenon in your area, then it is better to choose a product with a thickness of 6 mm. It is these products that are most often used by the gardeners of our country. But this material costs a little more.

An increase in this indicator has a positive effect on the service life of the structure. An increase in this indicator from 4 to 6 mm increases the durability of the greenhouse by about 10 years.

If the cultivation of plants in the garden or in the garden takes place all year round, then it is better to use sheets with a thickness of 8-10 mm. Such products will be able to withstand the weight of the snow. In winter greenhouses, a prerequisite for the operation of such products is the heating of the structure from the inside.

In addition, the choice of the thickness of the finish should be made based on the size of the structure itself. For large greenhouses, a thickness greater than 10 mm should be used. A high level of strength in this situation will allow you to finish not only the roof, but also the load-bearing walls.

As you can see, the best solution would be to use a 6 mm thick material. You only need to choose another option for this parameter if you have certain needs (for example, increased strength).

Determining the type of polycarbonate

Today, these plastic sheets can have a variety of structures. As a result, this material can be:

- cellular;

- monolithic.

The difference between the two is that the honeycomb has a honeycomb structure. For a greenhouse and a greenhouse, the optimal solution would be to use a honeycomb material. This material has better characteristics than a monolithic structure. A monolithic material is characterized by greater strength, but also greater weight, as well as lower thermal conductivity. Namely, these qualities are very important when assembling a greenhouse.

As you can see, polycarbonate (especially the honeycomb type) is an excellent solution for a greenhouse of any design and size. Correctly selected thickness of its sheets will allow you to get not only a durable, but also a warm greenhouse. And this, in turn, will provide you with a quick and bountiful harvest.

Video "Greenhouses for cellular polycarbonate"

A gardener who is going to build a greenhouse has one task: to ensure its maximum reliability and durability. How to achieve this, you will learn from the video.