How to build a gable polycarbonate greenhouse with your own hands

Content

What are the features

Polycarbonate is a special transparent sheet material that has become indispensable in the construction of greenhouses, displacing glass and film, which were traditional materials. Polycarbonate is easy to cut (with a conventional knife), very lightweight and flexible.It is 50 times stronger than glass and 16 times lighter, and 500 times stronger than film.

The polycarbonate material will withstand heavy rain and hail. Manufacturing firms give a 15-year guarantee on it, which indicates the durability of the material. But, the main thing for a vegetable grower and amateurs is the increased thermal insulation and the ability of polycarbonate to transmit and diffuse light.Polycarbonate is a plastic made of two sheets, interconnected by stiffening ribs, of the same material. Inside, voids are formed, very similar to honeycombs, from which the name comes from - cellular polycarbonate. This interesting design has many advantages. Experiments prove that one sheet 6 meters long weighs only 10 kg.

Operating temperature from -50C to + 120C. The heat is retained in the greenhouse, and the light penetrating through the plastic membranes is most favorable for the plants. Suitable for use in harsh environments. Withstands enormous loads (200 times more than glass). When using polycarbonate in greenhouses, check if it is equipped with a UV layer. This layer is fused into the face of the structure and protects the plastic from the sun.

Design and installation

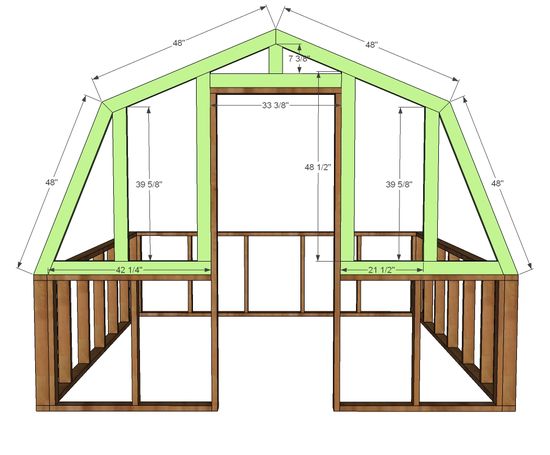

Diagram of a gable greenhouse in the figure

The most common greenhouse is considered to be a gable. It has a fairly simple drawing - two planes converging upward and end walls. Often, gable greenhouses are made by hand as free-standing ones, not attached to a structure. The disadvantage of this type will be the small area, and in the cold time of the day there is also insufficient heating of the plants, since all the warm air will collect under the roof.

You can build ordinary vertical polycarbonate walls with your own hands, and make the roof in the form of a triangle. The advantage of the latest design is the spacious arrangement of your plants. Some lovers of fresh nature, in such greenhouses arrange recreation areas where beautiful rose gardens are planted.

When choosing a location for a greenhouse, there are three factors to consider:

- light mode (install the greenhouse from west to east along the length);

- wind directions (think over wind protection);

- wide and convenient passage (to facilitate construction and future operation).

Greenhouse frame drawing in the picture

We begin to draw a drawing with our own hands, prepare the necessary materials, and carry out calculations. We will choose the size of the greenhouse based on the size of a standard polycarbonate sheet - 2.1X6.0 m. So, from two sheets you can get 8 pieces of 2100X1500 mm. And build a greenhouse with a straight wall size of 4200X1500 mm.The width of the room depends on the slope of the roof slope. The height of the greenhouse, if we use one cut sheet, will be 1.5 m.But if we build a foundation 20 cm high, the height of the wall will already be 1.7 m.

For the frame frames, we take a profile steel pipe, for example, 40x20 mm. It is easier to attach polycarbonate sheets and frame elements to a profile pipe. The pipe section at the metal base is 6.05 m.Let's consider the option of making a frame with our own hands from one steel pipe (see the drawing below).

Frame drawing without measurements. With a height of 1.7 m, a 3.4 m pipe will be required for a gable greenhouse. From the remaining piece of 2.65 m and with a roof at an angle of 30%, we make a frame width of 2.24 m.With these calculations, we will cover the greenhouse with one sheet of polycarbonate with protruding side overhangs of 10 cm (for water drainage).

We make a foundation with our own hands with a depth of 40 cm, we lay anchors around the entire perimeter for fastening the profile pipe, fill it with concrete. After drying, we proceed to the installation of the frame.

Frames and trusses for the greenhouse must be cooked with your own hands on the ground, and only then the entire structure must be installed. There must be a door on the front elements, on the other side there is a window. All elements are welded together and attached to the foundation (see drawing).

We can lay polycarbonate sheets with our own hands with overlapping layers or using connecting profiles, they are installed between the sheets. For fasteners, special thermal washers are used. The thermal washer additionally protects the material from dust, dirt and seals the connection.

Video "Greenhouse from cellular polycarbonate"

Lighting and heating

What to do if you want to have a working greenhouse that brings benefits and harvests all year round? It is necessary to provide for heating and lighting in the structure. To choose the right type of heating system in a greenhouse, you need to take into account its size, distance from home or kitchen, if joint heating with your home is planned and, of course, the amount of money that you are willing to allocate for this.

The cheapest and most common is heating a greenhouse with hot water using solid fuel. Also, quite often, dark-spectrum infrared lamps are used to heat individual greenhouses. They make it possible to instantly adjust the temperature in the greenhouse, do not take up much space, destroy harmful fungi and are completely automated.

To heat the greenhouse with gas throughout the year, you need to connect to the city gasification system with your own hands, but if you only need to adjust the temperature jumps, a connected gas cylinder or tank with liquid gas will do. There is a cable heating system that is economical to operate, inexpensive to install, and evenly distributes heat. To install such a "warm floor" with your own hands, part of the soil is removed, a layer of sand is filled in, and then the cable is laid with a snake.

Electric heating with a conventional radiator. Finned radiators with thermostats of different lengths and powers distribute heat along the entire length of the case, and in combination with a greenhouse fan, they are able to supply heat in different doses, quickly react to sudden temperature fluctuations and prevent moisture from forming on the greenhouse walls. Heating of greenhouses due to heating systems at home is also in demand.

Everyone knows that plants need 12-16 hours of daylight hours. If the length of the day becomes shorter than 10 hours, the plants simply stop growing. But scientists have found that special illumination of the red spectrum is "useful" while the flowering is in progress and the fruit is being set, and the blue one is for vegetative growth.

Based on these findings, there are many options for special greenhouse lighting. Conventional incandescent lamps illuminate the greenhouse well, but not always favorable for seedlings, growing fruits. Not economical. Fluorescent lamps are quite economical.They have a beneficial effect on plants, are durable and inexpensive, but do not have high heat transfer.

High pressure mercury lamps heat up quickly, are beneficial for all plants, but you need as many of them as possible, since the range of the lamp is not great. Metal halide lamps with a wide power range. They are considered ideal for greenhouses, unfortunately, they are not durable and expensive. Also, they are not convenient due to the special requirements for the combustion position. High pressure sodium lamps. They have high heat transfer, are economical, create a pleasant yellow-orange light in the greenhouse, simulating sunlight. But they are not suitable for vegetative growth.

LED lights allow you to illuminate the greenhouse with the desired light thanks to the attachments. Economical in electricity consumption, they are not cheap. The most constructive option would be to mount greenhouse lamps in a row on flexible cables, which will allow you to adjust the height and orientation of the light sources.

Video "Installing the greenhouse with our own hands"

This video acts as a visual aid that will help you decide how to properly build a factory polycarbonate greenhouse.