We do water heating of the greenhouse with our own hands

Content

Advantages

In winter, it is necessary to provide the plants planted in the greenhouse with stable heating of the air and moderate humidity. There are several types of heating systems that will cope well with this function in a building with a polycarbonate coating: gas, air, electric, infrared, biofuel. However, each of them has a number of disadvantages and difficulties in operation, in comparison with water heating.

Water heating stably maintains the required air and soil temperature, while humidifying the air, which will benefit any garden culture in a polycarbonate structure. Despite the fact that assembling water heating may seem unnecessarily expensive, during operation this option pays for itself completely. Heating with water works on any combustible material: wood, peat, garbage, biofuel, gasoline.

It should be borne in mind that the system of pipes and boilers is safer than electrical cables, which can be damaged, or gas heating, which is associated with the risk of explosion or fire. Moreover, making such heating is much easier with your own hands.

The specificity of polycarbonate, as a coating for a greenhouse, is that in winter it does not tend to collect condensation on the walls. Consequently, moisture generated in the air will return to the ground, moisturizing it naturally in winter. Thus, water heating, which is easy to make with your own hands, is one of the most profitable options for use in a greenhouse.

Greenhouse water heating video

How to make water heating in a greenhouse with your own hands is described in the video.

Calculation of the water system

To make the correct water heating with your own hands, you should carry out a basic calculation of the required number of pipes, boilers, as well as the capacity of the system. It should be based on the total area of the room, air temperature and outdoor temperature (average).

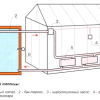

The very same water heating mechanism is created from a boiler for heating, several pipes, two radiators, an expansion tank and a chimney. Depending on the means at your disposal, you can install a gas or electric boiler, or install a stove for kindling with peat, wood. A more ergonomic and cost-effective option is a gas boiler.

Universal pipe laying scheme - two working circuits. The first is in the soil and consists of pipes filled with water. The water temperature in this circuit is 30-40 ° С, the main purpose is to heat plant roots. The second circuit is used directly for air heating. In a polycarbonate greenhouse, you can install a thermostat so that the desired temperature is automatically maintained.

To install radiators with your own hands, you need to decide on the material from which they are made: cast iron, bimetal, aluminum. An expansion tank can be made with your own hands from a sheet of metal, or you can buy a ready-made one.

The chimney, as the final stage of the heating system in a polycarbonate greenhouse, can be created from bricks if you do not want to complicate the process. Another option is metal or asbestos-cement. Here you should only rely on your ability to build the correct ventilation system with your own hands.

Mounting

Since the plants should already be in the polycarbonate greenhouse in winter, the heating should already be on. Therefore, the installation must be done in the fall in order to have time for testing and calibrating the system.

We recommend placing the heating boiler in the greenhouse dressing room so that it does not take up space in the room itself, but at the same time there is free access to it. A separate foundation made of asbestos cement or steel is allocated for the boiler. When choosing a material, one should rely on its characteristics of fire resistance and fire hazard. The expansion tank is located at the highest point in the room, next to the heating boiler. Install an air shutoff valve and pressure gauge for safety reasons. Also leave room for the outlet of the chimney, make sure that all joints are hermetically sealed. This will prevent smoke from the dressing room, as well as loss of system performance.

The next stage is a ventilation system, which is especially necessary in winter, even in a polycarbonate greenhouse.

If you chose plastic pipes, then do not connect them directly to the nozzles of the heating boiler, first connect metal pipes to it, and already plastic pipes to them. Do-it-yourself pipe installation is quite simple. The first contour is laid in the ground not less than 40 cm, but not more than 60 cm in depth. They should be laid at a distance of 30 cm. After the pipes have been laid, radiators should be installed.

Keep in mind that during the heating process, water will rise into the expansion tank and only from there will spread through pipes to all corners of the room. Therefore, pipes should be installed at a slope.

As you can see, it's not so difficult to create water-based heating in a polycarbonate building with your own hands, while the result in the form of a rich harvest will pay off all your efforts.

Greenhouse Heating Video

How to make heating in your greenhouse is described in detail in this video.