We build a closed gazebo for a summer residence with our own hands

Content

Types of closed structures

The main advantage of closed buildings is 100% weather protection. Depending on your own preferences and financial capabilities at the summer cottage, you can install:

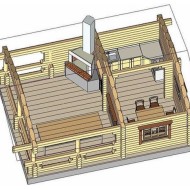

- Finnish house with an area of 10 to 18 squares. This refers to a building of a standard form with autonomous exhaust ventilation, in which it is realistic to equip a kitchen area.

- Fully glazed buildings, where it is light and comfortable at any time of the year. Transformer gazebos with sliding walls are especially popular.

- Semi-closed structures with forged decorative elements and wooden battens. This is the best solution for summer and off-season.

- Brick outbuildings with external and internal electrical wiring. They belong to capital construction projects, therefore, they need state registration.

It is important to decide on the type of roof and foundation at the design stage of the gazebo.

Video "Closed gazebo with a pond with your own hands"

In this video, you will learn how to build a wooden gazebo with an artificial reservoir.

What to build from

In answering this question, most experts lean towards the tree. Pine, for example, lends itself well to grinding and staining. Its unique white-pink color, combined with the loose structure of the wood, creates unusual decorative elements. For gluing volumetric components with your own hands, a spruce is more suitable. And if you need to increase the shelf life of the structure by at least 10 years, it is better to build the walls from larch.

Resins predominate in the composition of this material, which sometimes complicates the processing of raw materials with professional equipment. However, unlike pine, it has a higher resistance to warping. Larch hardly absorbs moisture and is ideal for making carved parts.

Yew can withstand temperature changes better. And if it is necessary to implement the method of artificial aging, carpenters recommend sticky oak wood.

Most modern builders prefer steel structures. Their advantages include:

- high strength, density and impermeability;

- maintainability;

- a light weight;

- fine-grained structure, which increases the reliability of structures;

- good resistance to mechanical damage and dynamic loads during installation;

- long period of operation in regions with different climates.

The construction of two-story gazebos of a closed type is unthinkable without brick products. Products of the M-150 brand, suitable for the construction of walls and laying foundations, are in special demand. Hyper-pressed bricks surpass even silicate bricks in strength, but unlike ceramic products, they exert large loads on the supporting structures. Therefore, when choosing building materials, it is important to take into account not only their physicochemical or, say, aesthetic properties, but also the features of the buildings themselves.

Drawing creation

First, you need to draw up a detailed plan of the suburban area with the designation of the main and additional buildings.This will help you choose the best place for a gazebo, located a few meters from the house or at the farthest point of the front garden. It is better to install glazed structures equipped with barbecues 10 m from the main building and about 8 m from the border with a neighbor's house.

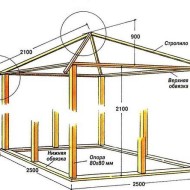

When drawing up a drawing, do not forget about the foundation. For example, lightweight metal and wood structures will require a columnar base. The optimum distance between vertical beams is 1800 mm. If they plan to install heating devices in the gazebo or even organize an open hearth, it is important to decide in advance on the size of the stove. The ideal barbecue depth is 800 mm and the width is 950 mm. To avoid accidents, tables and chairs should not be placed in the immediate vicinity of the barbecue maker.

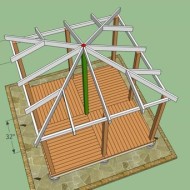

In the drawing, it is important to indicate not only the location of structural elements, but also the shape of the buildings. For example, a rectangle is more suitable for a convenient arrangement of furniture. And if the building is being built for business negotiations, a circle or an octagon. Elementary lighting and ventilation schemes should be performed in an isometric projection with an indication of the height parameters.

Construction procedure

Shovels, a building level, a tape measure, a circular saw, hammers, pliers and self-tapping screws will come in handy in the work. For the foundation - sand, cement, crushed stone, beams and asbestos pipes. Getting started with the main processes, it is important:

- make a markup of the site;

- dig holes for pipes, and then fill them with cement-sand mortar;

- strengthen the foundation elements with beams;

- make waterproofing of supporting structures;

- install intermediate beams and logs;

- lay the floors and fix the upper harness of the gazebo;

- prepare the rafter system and fences;

- fix the window frames with self-tapping screws and paint the already finished structure.

The foundation

If we take a columnar foundation made of concrete blocks as a basis, the main thing is to choose the right site for construction. In this case, the marked place must correspond to the dimensions of the base.

Next, we remove the 30-centimeter layer of earth, compact a soft cushion of rubble and set the blocks on a cement-sand mortar. In work, it is better to use the product of the M-400 brand. It withstands heat, frost, increased moisture and frequent temperature changes well. Even if you deviate slightly from building technology, the likelihood of cracks will be minimal.

From above, the pillars should be treated with roofing material. This will increase the resistance of structures to adverse seismic events. The grillage, evenly distributing the loads on the supporting elements of the structure, is mounted on self-tapping screws. In works on areas with unstable soils, the installation of a monolithic reinforced concrete belt will be required.

The construction of two-story gazebos with autonomous heating involves the use of a strip base. For this you need:

- make markup;

- dig trenches;

- prepare a 25-30 cm thick sand drainage cushion;

- build a formwork;

- mix a solution of sand, crushed stone and cement in a ratio of 2: 5: 1;

- install frames if necessary.

Walls

It is better to sheathe the outer surfaces of the gazebo in the country with polycarbonate. This material is highly resistant to mechanical stress. It transmits light well, but at the same time scatters ultraviolet light, which is especially important during periods of extreme heat. In order to avoid technical errors, it is better to erect walls according to a previously drawn up drawing. A screwdriver, a plumb line, as well as tools for cutting metal are useful in work.

If you need to improve the appearance of the structure from the outside, it is better to use the clapboard. To do this, new beams or sawn timber should be filled under the lower beam and railing. Reinforced clamps and decorative nails will provide reliable fixation of the lining.

The indisputable advantage of glass walls is the visual expansion of the space.In such gazebos, heat is well retained, and natural lighting allows you to work without lamps almost until the first dawn. The only drawback of such surfaces is the one hundred percent visibility of the residents. But given that gazebos are installed mainly in fenced yards, this is more an advantage than a disadvantage.

A planed board is also suitable for cladding. In regions with dry climates, such as Crimea, it is better to use breathable reed panels.

Roof

A pitched roof is a reliable option for a completely enclosed gazebo and every second frame structure. The rafter system includes softwood elements. It lends itself well to grinding and cutting. Requires pre-treatment with antifungal agents before use. To protect structures from increased moisture, you should use basalt wool and a vapor barrier film. Depending on the operational characteristics of the roofing materials, you can choose the beams with the optimal cross-section for the battens.

It is better to cover a large gazebo 10x12 m with soft tiles or corrugated board. The latter is famous for its high bending strength, and the low cost of the profile makes it popular among an unlimited number of consumers. Metal tiles can be laid on a wooden base. Ondulin resistant to aggressive environment - on plywood.

Windows, doors

In closed annexes, products with single-chamber double-glazed windows are often used. They retain heat due to inert gas, but in frosty weather they quickly fog up and freeze. In this case, it is more profitable to use windows with double-glazed windows. In winter, such products retain up to 45% of the heat, and condensation forms only at temperatures of 15-17 ° C below zero. Three-chamber double-glazed windows are held in high esteem by residents of the northern regions of the country. They are 2 times heavier than previous designs, but their energy savings are 37% higher.

Products with ventilation valves facilitate regular ventilation of the room. If you need to close not only window but also wall openings, buy a frost-resistant film. It retains only 20% of the heat, but guarantees good protection from rain and wind.

Interior decoration

When choosing materials for wall cladding, it is better to prefer a block house or wooden slats with a section of 40x50 mm. The interior can be glued with double-layer vinyl wallpaper. They almost do not allow liquid to pass through, and the variety of patterns contributes to the implementation of stylish design ideas. The floors should be painted with wax based compounds. So you will be able to increase the resistance of wood to moisture and temperature extremes. If it is important to emphasize the exquisite texture of the material, it is useful to stock up on transparent coatings.

For decorating furnace complexes and pillars, a facing stone is suitable: quartz slate or travertine.