We build a polycarbonate veranda quickly, easily and reliably

Content

Types and advantages of material

Polymer plastic, or polycarbonate, belongs to the group of new generation building materials. There are two types of polycarbonate: monolithic and cellular. Solid sheets are solid sheet plates that are highly flexible. The honeycomb polymer consists of two sheets interconnected by transverse bridges. The degree of rigidity and, accordingly, the strength index of the material depends on the number of inner membranes. For this reason, cellular polycarbonate is called structured, cellular or membrane.

Polymer plastic is widely used in construction and agricultural fields, medicine and outdoor advertising. The advantages of the material include the following technical characteristics:

- High impact resistance and resistance to mechanical damage.

- UV protection from direct contact with sunlight.

- The possibility of uniform dispersion of sunlight, which makes it possible to use the material for sheathing the roof of various architectural objects.

- Moisture resistance and excellent thermal insulation.

- Resistance to various atmospheric precipitation.

- No difficulties with installation and operation of the finished structure.

- Light weight and high flexibility.

Video: "Do-it-yourself glazing of the veranda with polycarbonate"

This video tells how to make the glazing of the terrace attached to the house with polymer plastic.

Variety of design options

The popularity of the polymer-clad veranda is rapidly gaining momentum. The style and design of a polycarbonate veranda depends on the characteristics of the climatic zone, location, purpose and functionality of the facility.

By the shape of the frame, structures are square, rectangular, polygonal, triangular, oval and non-standard. As for the installation site, often the veranda is built separately or attached to the house. Climate features determine the type of building, therefore there are open, semi-closed and closed verandas.

Detailed technology

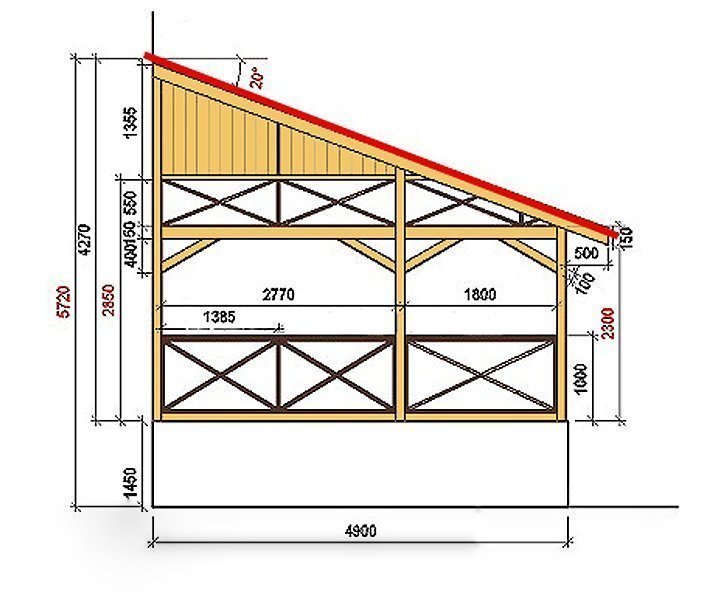

At the preparatory stage, it is recommended to carefully think over each stage of construction and draw up a detailed project of the future structure. The dimensioned schematic drawing helps to avoid many mistakes common among novice builders. You can correctly draw up a sketch using specialized drawing programs: nanoCAD, autoCAD and "Compass-3D".

To work with polymer plastic, you will need sawing tools, a sealed tape for processing the ends, self-tapping screws with thermal washers, an electric drill with a set of drills of various diameters. In the process of erecting a terrace attached to the country house, tools and materials will be needed for pouring the foundation, installing load-bearing supports, installing walls and roofing.

Foundation

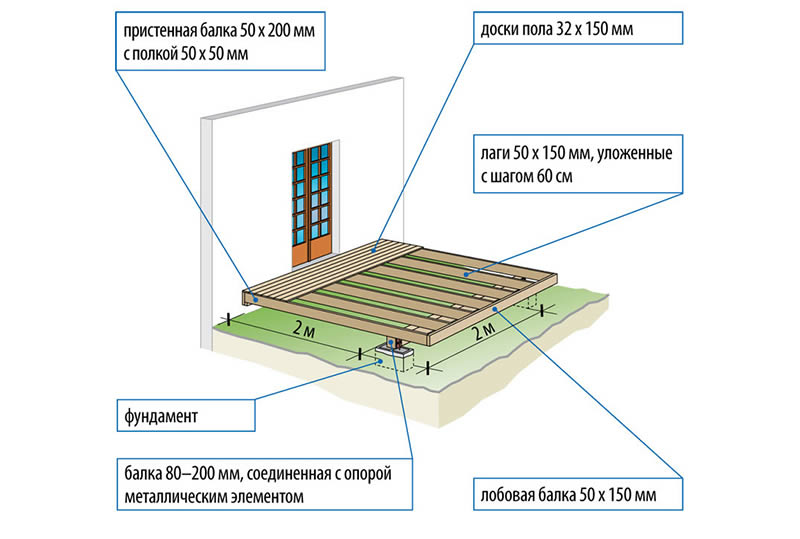

The first stage of construction is marking the site and installing the formwork.Keep in mind that if the terrace is built-in, then further installation of the bearing supports is carried out on the foundation of the country house. A veranda attached to a house or bath requires a solid and reliable foundation. The best option is to fill a strip, columnar or monolithic foundation. When forming a concrete base, the flatness of the horizontal plane is checked. Improper pouring and skewing of the foundation can cause deformation of the walls of the building.

Some builders who prefer lightweight building structures propose to do without a foundation altogether. Over the entire area of the future building, sand and fine gravel are covered with layers, stone, concrete or clinker tiles are laid on top.

Load-bearing elements

The choice of material for supporting structures is determined by the model of the veranda and the architecture of the house. So, near a wooden country house, it is better to build an extension from a bar and boards. If it is planned to build a canopy in the form of an arched structure, then you cannot do without a steel or aluminum domed frame. At the same time, the steel structure is considered more durable and reliable, since it can withstand a large snow load.

When erecting an arched type of metal verandahs, it will be necessary to install transverse stiffeners and additional pillars. To strengthen the strength, it is recommended to lay the load-bearing elements at the stage of pouring the foundation.

Wall and roof cladding

For wall and roof cladding, cellular polycarbonate with a protective UV coating is used. You can determine the side of the ultraviolet light by the markings from the manufacturer.

To cut the polymer canvas, you need to clean the work surface from construction and household waste. The ends of the polymer plastic should be closed with a sealed tape and an end profile. Otherwise, the accumulation of moisture, dust and debris inside the polycarbonate will lead to the loss of the original physical properties and qualities of the material. For the installation of polycarbonate, you will need a detachable metal profile, self-tapping screws and thermal washers.

Decorative finishing

At the final stage of the construction of the polycarbonate veranda, decorative finishing is carried out. If a metal profile has been chosen as a supporting element, the material should be coated with a special anti-corrosion agent that prevents moisture penetration and the appearance of rust. Wooden supports are treated with fire retardants and antiseptics, which help to increase the fire resistance of the material and protect it from decay.

Large panoramic polycarbonate windows installed instead of walls do not require additional decoration. A planed block-house board, which is a segment of a profiled bar or a rounded log, is used to decorate the lower end panels. Also, this material is interesting to complement the window shutters.

For the interior decor of the veranda, fabric drapery, lighting and flower pots of various colors are used. Blooming, curly and coniferous ornamental crops arranged around the perimeter of the building create a warm and homely atmosphere.

Building Tips

Despite the high strength, it is necessary to work with polycarbonate sheets carefully and accurately. Dents and scratches left during the installation process lead to a deterioration in the technical qualities of the material. Fastening of overlapping panels is the main reason for the early depressurization of the structure. For this reason, it is recommended to leave a minimum gap for the panels to separate.

Please note that the wrong choice of detergents leads to the loss of the original physical properties of the polymer plastic. To clean the polycarbonate veranda, do not use abrasive detergents and brushes with stiff bristles.

A veranda lined with polycarbonate is a quick, simple and reliable way to improve your summer cottage.Even a summer resident who does not have special skills and practical experience can make a functional extension, if he approaches this task with all responsibility.