Do-it-yourself tandoor: Asian cuisine in your country house

Content

What is tandoor

First you need to understand what dishes were prepared by the inhabitants of the East. The stationary tandoor, installed in the dwelling, had various sizes, and was intended not only for cooking, but also for heating. This massive furnace reached 1 m³ in size and weighed up to a ton. Using the specific properties of the brazier, Asians made flat cakes, samsa, pilaf, lamb, vegetables. Due to deep baking of the product, it was possible to endow any dish with a special aroma. It is impossible to achieve such a result on a regular grill or in a stove.

Video "Brick tandoor with your own hands"

From this video you will learn how to independently build a high-quality brick tandoor for a summer residence.

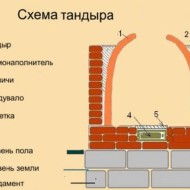

Brick tandoor

Anyone with little construction skills can easily master the construction of such a wonderful stove. First, you need to make a design diagram indicating all dimensions and clearances. In the absence of cast iron grates for the tandoor, you will need to complete a drawing and order them.

For the construction of the tandoor, a ready-made clay insert or the method of forming a jug-like surface inside the brickwork can be used. If you purchase a ready-made tab, the construction process will be much easier and faster. To make such a tab with your own hands, you will need heat-resistant clay. Any of these options will start with the construction of the skeleton.

Foundation

- It is necessary to mark a flat area for a monolithic foundation. Only this type of frame will be able to withstand the weight load of the future furnace.

- Next, a pit is dug with a depth of 15–20 cm. The bottom is covered with crushed stone and sand for the construction of a sandy base at a depth of 5 cm.

- Formwork is being built and the inner part of the pit is reinforced with metal profiles and rods. Steel products are tied with wire.

- The concrete solution is poured into the pit so that the foundation surface is 15 cm above the ground level.

- The skeleton is allowed to dry for several days. In hot weather, it is covered with a film so that cracks do not appear.

Wall masonry

- First of all, the inner chamber of the tandoor is laid out. From the very base, it has a round shape, the diameter of which is 1 m. The bottom of the combustion chamber is completely covered with bricks.

- In the bottom row, a traction passage is left, which will act as a blower. The second row is laid with bricks, leaving space for the grate.

- A cast-iron grate is installed horizontally in the middle of the chamber. She sits on a sandy-clay mortar, by means of which the refractory bricks of the tandoor furnace are laid. All subsequent rows are laid with fireclay bricks vertically along the perimeter of the outer diameter of the combustion chamber. Outside, the brickwork is covered with steel wire.The resulting rings are rigidly pulled together and fixed.

- The height of the brazier does not exceed 1.5 m. The upper rows are placed with a decrease in diameter so that a jug-like conical shape is obtained inside the chamber.

- The inner cavity of the laid out chamber is covered with a layer of clay and carefully smoothed out. It is on this surface that the dough of future cakes will be baked. The outer part of the firebox should be covered with a layer of clay.

- The external masonry of the miracle stove can be built in the form of a circle or a square. It is carried out with a small gap from the combustion chamber at a distance of 10–12 cm from the edge of the foundation. The height of the masonry is leveled with the brazier, while the outer walls are made vertical.

- The gap that remains between the combustion chamber and the masonry is filled with heat-saving material. For this, sand, salt, fine gravel or stone chips are used. This layer will keep the heat in the chamber for a long time. From above, the layer is covered with clay mortar and laid with bricks.

Hole closure

Depending on the purpose of the tandoor structure, the lower hole intended for traction may not be closed at all. Typically, a door or adjustable air damper is installed on this cavity. For the upper hole through which firewood and food is laid, a round wooden lid with an outer handle is made. This homemade flap should fit snugly against the top of the neck to keep warm inside. For some dishes, it is not necessary to cover the top completely. In these cases, a specially made flap is used, which partially covers the feed opening.

Decorating

After building the tandoor and making the lids, it's time to do the exterior design. One of the design options can be natural stone laying on the outer surface. This design will improve the ability to retain heat inside the brazier.

Tandoor with ready-made tab

The properties of the inner surface of the tandoor make it possible to achieve high-quality baking of dishes. To save time, use a ready-made insert, which has the shape of a jug without a bottom.

After laying the first two rows of bricks and installing the grate:

- the finished tab is placed in the middle of the building;

- set on clay mortar;

- bricked.

Preparing a tab

- To make the tab yourself at home, you need fireclay clay of medium viscosity and normal plasticity. It is thoroughly mixed with salt, sand and wool in a ratio of 4: 1: 1: 2. Clay must be cleaned of various impurities. Sheep wool is used for reinforcement and thermal insulation. The solution is thoroughly mixed with water until a sour cream consistency is obtained.

- From the resulting solution, strips with a size of 2000x200x20 mm are made. The process must take place in the shade so that the clay does not lose its elastic properties.

- The stripes form a kind of bowl, which has no bottom. For this, a cylindrical frame is used, pre-oiled to facilitate its subsequent removal. This work is done in the sun.

- The next element of the tab is a dome, which is also formed in the sun. The lower diameter of the dome is made the same as the size of the bowl, and the upper one is half as large.

- We carefully connect the two halves of the future inlay using the method of sealing surfaces and a special tool in the form of a trowel with a diagonal embossed pattern.

- After connecting the cone to the bowl, the neck of the inlay is formed. At the top, the clay is compacted to increase strength.

The tab is ready! After drying, it is installed on the lower rows of the masonry.

Foundation

- A site is marked for the device of a monolithic foundation.

- A pit 20 cm deep is pulled out, a sand pillow is made.

- Formwork is made, the inner part of the pit is reinforced.Unnecessary metal profiles are used for reinforcement.

- The inner cavity is concreted with mortar to a height of 15 cm from the ground. Using the rule, the surface of the skeleton is aligned with the level.

Now the foundation needs to dry. It will set for 3-4 days. During this period, it is impossible to carry out any work.

Wall masonry

- First, the bottom is laid out under the tab and the outer walls of the tandoor. From the very base, it has a round shape, the diameter of which should be 1 m.

- In the bottom row, a traction passage is left, which will act as a blower. The second row is laid with bricks, leaving space for the grate.

- In the middle, a cast-iron grate is installed on a sand-clay mortar.

- The tab is installed in the middle of the building. The lower part is coated with a heat-resistant clay solution.

- After installing the tabs, proceed to the construction of the outer walls. The perimeter of the tandoor is made in the form of a circle or square. The outer walls are laid out of red bricks at a distance of 10-15 cm from the edge of the foundation.

- Upon completion of the brickwork, at the level of the neck of the inlay, the gap is filled with heat-insulating material (such properties are possessed by sand, stone and salt).

- The upper part of the furnace is laid with bricks, the opening of the insert is left free. To make a tight lid of the future tandoor, they take a ring from an old barrel, and a larger diameter than the opening of the tab. Install it in the upper part when laying the surface with a brick. This ring will become the outer contour of the upper flap.

Allow the tandoor to dry. Then, gradually heating it up, it is finally dried.

Earthen tandoor

One of the popular varieties is the Armenian earthen tandoor. The variety of designs suggests its manufacture even with a horizontal axis of location. Let's look at how to build a tandoor in the ground on your site:

- A place is selected taking into account the fact that it will be impossible to transfer this oven.

- A project is being executed, which will contain diagrams and sketches of the structure. The project provides for the height of the tandoor at a level of 15-25 cm above the ground for ease of use.

- A plot is marked out for carrying out earthworks.

- A hole is dug, the diameter of which should exceed the size of the future furnace by 1 m. The depth is done in accordance with the project. A recess for the blower is left.

- At the bottom of the pit, a sand cushion 5 cm high is organized.

- With the help of clay mortar, the bottom is laid out with refractory bricks. On the side where the blower will be, a small cavity is left in the form of a gutter that goes under the future wall.

- With the help of clay mortar, round walls of fireclay bricks are laid up to the design height. The Armenian design does not provide for the conical convergence of the combustion chamber.

- On the side of the blower, a metal pipe with a knee is installed, which will go into the gutter at the bottom.

- The internal walls are coated with clay mortar and the surface is carefully smoothed.

- The outer surface of the masonry is reinforced, then it is covered with a thick layer of clay.

- A wooden flap is made for the upper cavity of the resulting combustion chamber.

The main work on the construction of the tandoor in the ground has been completed. Now you need to let it dry for 2-3 weeks. During drying, the gap between the masonry and the ground must not be filled up.

After the combustion chamber has completely dried, the pit cavity between the firebox and the ground is filled up. For this, it is better not to use dug soil. A material that retains heat is more suitable. It will be enough to use sand and stones.

Tandoor in the Uzbek way

The main material for the manufacture of such a furnace is clay, which is thoroughly mixed with sheep's wool.Reinforcement of the inner part is made of fireclay bricks, and sometimes just from kaolin - this is such a heat-resistant material that consists of minerals and is used in the East in the construction of furnace equipment. People call it white clay.

Cheaper and faster option

In addition to stationary ones, Uzbeks made portable jug-shaped tandoors. Such ovens are very economical and allow you to cook a cake or pilaf on a few dried camel thorns and roots. Portable kilns possess such properties due to the consistent technology of making clay and its subsequent firing. Using the material at hand, the manufacture of portable tandoors did not require much effort and expense.

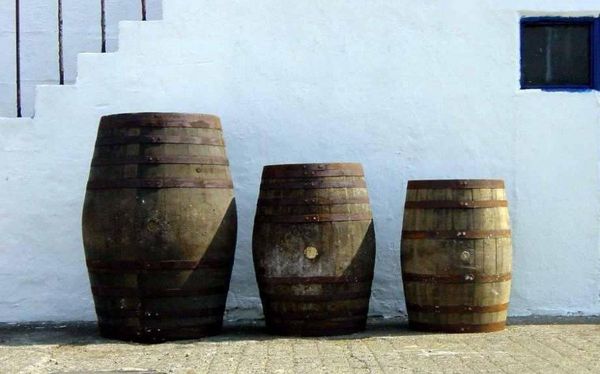

Tandoor from a wooden barrel

The unpretentiousness and simplicity of Uzbek technologies make it possible to use various materials in the construction of the furnace. Let's figure out how to use a wooden barrel to build oven equipment:

- A whole, preferably oak barrel is selected, the rings are loosened, after which it is filled with water. It will take 5 days for the water to be absorbed into the wood. The heavy container is turned upside down.

- During the day, the barrel is allowed to dry out. The inner surface is lubricated with sunflower oil. After impregnation with oil, leave for another day.

- While the barrel dries up, prepare the clay mixture. The finished mixture is rolled out and strips are made from it, corresponding in length to the diameter of the barrel. They are made flat with a width of 7-10 cm.

- The inner cavity of the barrel is completely sealed with these strips, which are overlapped to avoid cracks and hollow parts.

- In the throat of the combustion chamber, a gradual narrowing is made to comply with the thermal regime.

- After laying out the strips on the inner surface, they are smoothed as much as possible. Minimizes any irregularities.

- After all this, the barrel with clay walls is dried. This process takes a whole month. It is best to place the assembled structure in a windy place under a canopy.

- As it dries, the clay will begin to separate from the sides of the barrel. This must be closely monitored.

- When the clay is completely dry, the barrel is disassembled, having received a finished clay oven.

This combustion chamber serves as a tab. It is placed on a foundation and covered with bricks.

Iron barrel tandoor

An iron barrel is used as a template for building a clay chamber - just like a wooden one. Only a metal container does not have to be soaked in advance. All actions of the technological process will be the same, except for the last one: after making sure of the strength of the dried clay, the barrel is carefully cut with a grinder in height and the clay oven is pulled out of it.

Preparation for work

After two weeks of natural drying, the finished structure can be gradually heated, gradually increasing the temperature inside the chamber. Thus, the inner surface of the clay will be fired. The firing quality is checked by lightly tapping on the inner surface. When a ringing knock with a slight echo is heard, it will mean that the tandoor camera is ready for operation.

Ready tandoor

If there is no desire to engage in the manufacture of tandoor, it can be purchased ready-made. They are portable and of various sizes. Such a wonderful stove will be an excellent replacement for a portable barbecue when traveling to the country. Today even electric heated tandoors are made. The heating element of such structures is a tubular electric heater.

The quality of cooking in electric tandoors differs significantly from cooking in the original ones. The lack of aroma of firewood and drying of the inner cavity with a tubular electric heater affects the taste of ready-made meals.

The considered designs of the eastern miracle stove can not only replace the grill or barbecue familiar to many. They will improve the quality of the food you cook. The vertical arrangement of the kebab or the installation of the cauldron directly on the coals seems to us at first a curiosity, but having tasted any of the dishes cooked in the tandoor, you forget about other types of oven equipment.

When building a tandoor, it is important to remember about the properties of heat-insulating materials and their application in accordance with the proposed recommendations.