Simple and original ideas for making a do-it-yourself bench

Content

Types of benches for giving

You can build a street bench in different ways, using almost improvised means. The most popular structures are made of wood, metal, stone, or a combination of these. It is so nice to relax on the bench after a long walk, enjoy nature, look at the starfall on a warm summer night.

The most reliable and beautiful are stationary summer cottages. As a rule, they are built on a good foundation. Often users choose metal structures. Usually, the supports are made of iron, and the seat and back are formed from boards. This is justified by the fact that the metal heats up quickly under the sun. Wood products look great. Support and seats with armrests in them are made of natural material. The benches need to be covered with an antiseptic to protect them from rapid decay.

The construction of stone looks original. To sit on it was not cold, the external appearance of the structure is complemented with pillows, wooden elements. To fasten the components of the bench, you will need a cement solution.

Video "Bench for the garden with your own hands"

This video will show you how to make a quality wooden garden bench.

How to do it yourself

The bench is not the most difficult structure, so you can handle it without any problems on your own. It should be remembered about the main components of the shop:

- support;

- seat;

- back;

- armrests;

- fastening.

Before starting the workflow, it is important to draw up a drawing, outline an action diagram. Consider the dimensions of the product, material, seating comfort, optimal height, etc. Before drawing up a project, think over the details, imagine the desired picture in your head. Remember to adequately assess your construction skills. If you know how to work well with wood, use this advantage.

From a log

This design fits organically into the natural landscape.

Log benches are:

- Mobile. Their location does not play a special role. The design requires good stability.

- On wheels.

- Dinner. They are placed next to the table, in front of the house, in the garden.

- Seasonal. Collected for the summer. They have a simple design and are easy to dismantle.

- Water. Installed near a reservoir, erected from a moisture-resistant material.

A seat in a bench made of a log is a large or medium diameter trunk sawn along a trunk. A similar situation with the back - a smaller trunk in diameter or a cut closer to the edge acts as it. The legs are made from narrow pieces of logs.

The structural elements of the shop are connected with metal pins. To avoid the appearance of marks after fastening, lay down an unnecessary board and knock on it with a hammer. The connection should turn out to be reliable, just in case, install 2-3 pins.

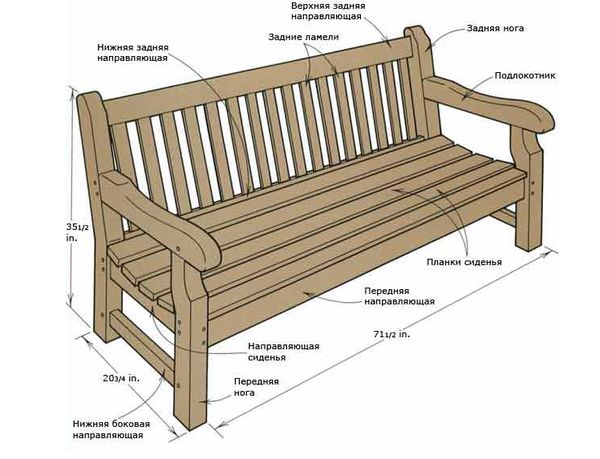

From planks

This is the classic version. You will need a modest set of tools: an ordinary plane, a saw, a screwdriver, a drill, a jigsaw, a varnish, etc. Responsibly treat the choice of material from which the shop will be made:

- oak - practical and tasteful, a breed resistant to the vagaries of the weather;

- hazel - attracts attention with a delicate color, looks great after varnishing, tolerates sub-zero temperatures without problems;

- cherry - has a reddish tint;

- needles are the best option for outdoor furniture.

After the selection of material and tools, the workflow begins.

Boards need to be adjusted to size, as an option - buy ready-made products. The wood is processed, the back and seat are sanded. It is better that the ends are rounded. Now is the time to set the angle of inclination of the rear support legs. A pair of boards 1 m long are taken and marks are made, while the 40-centimeter segment does not need to be processed, a 20 ° cut is made on the remaining part. The cuts on both legs must be identical. After that, the front and rear legs are connected using a bar and strapping. When the sidewalls are finished, they are connected with boards using self-tapping screws.

To strengthen the structure, it will be superfluous to mount another beam between the legs. The back is made, the boards are fixed at a distance of 20-25 cm from the seat.

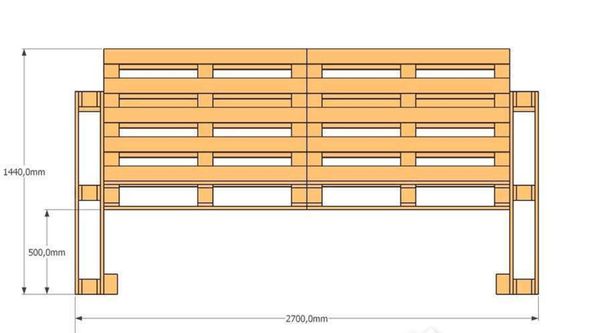

From pallets

Using imagination and physical strength, it will be possible to build a beautiful and comfortable shop. A striking example is pallet furniture. A whole pallet is taken, sawn into two parts, and one of them should be slightly larger. Prepared additional boards act as a frame. The back and seat are nailed. To increase the strength of the structure, the elements are connected with planks on the sides.

The product needs to be sanded. Four legs are screwed with a screwdriver. The bench is varnished.

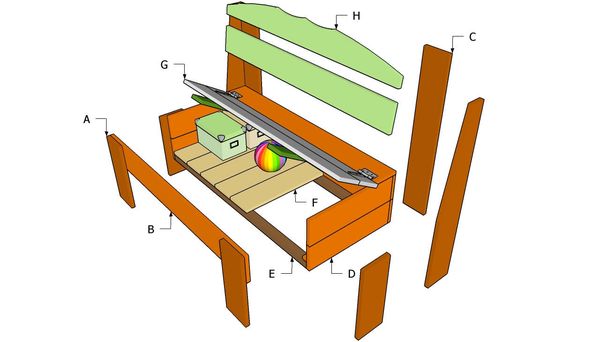

With box

An interesting option is a garden bench with a drawer and a wooden back. In a container under the seat, gardening supplies, tool kits, children's toys, etc. are usually stored. Before erecting a structure, you need to make a construction project. You should get a box of four frames with legs. The panels that are installed on the frames are plywood protected with a waterproof material. It is better to make a bench from durable wood - cedar or teak.

The design concept is simple: the seat also doubles as a drawer lid. A shop is being erected according to the standard algorithm, but the space under it is filled with a compact container. As a result, furniture can be used not only for recreation, but also for household purposes.

Metal

Besides the use of wood and stone, iron benches are popular. The main structural element is a metal frame. To create it with your own hands, it is recommended to use cold forging - to combine parts of the frame into one whole. In parallel, the product can be decorated.

The workflow is phased:

- It is necessary to draw up drawings of the future shop. If they are not there, you should focus on standard sizes. Optimum seat length - 1500 mm, width - 500 mm, backrest - 900 mm.

- The next step is the frame. First, a seat is made from several pieces of pipes. If there are no ready-made components, you need to make them yourself. To increase the reliability of the structure, add stiffeners to the frame.

- Pipes with a length of 450–600 mm will act as legs. Make sure the front and rear legs are connected to each other. This is necessary to increase the stability of the structure.

- The backrest is made so that the pipe lengths of 1.5 and 44 cm are welded to each other. After that, it is welded to the manufactured structure.

- The product is polished and coated with a primer.

- In order for the bench to have a finished look, you need to make wooden elements that will be on top of the frame. To do this, use a bar or board. The material should be smooth.

- All elements are connected. A jigsaw is suitable for this. Holes are made, parts of the structure are fastened with bolts and nuts.

- As a finish - wood treatment with wood stain or varnish.

The advantage of the design is durability and low weight.

Original ideas

The design for a bench in the garden can be different. In addition to the classic options, we suggest paying attention to the following designs:

- in the style of ethno or Provence - the priority is the combination of light elements with flowers, the natural landscape of the site;

- puzzle - curly seats are taken as a basis, which, after installation, will become a full-fledged bench;

- hex bench with backrest, etc.

The original home-made bench will organically fit into the gazebo, summer garden, and will pleasantly surprise guests with its appearance.

Decorating

The decoration of the furniture is intended to give it a complete look. To emphasize the design of the shop, it is enough to paint it correctly; forged details will also help to transform the look. To increase comfort in the summer, cushions, waterproof fabric can be placed on the bench.

A shop is not just a place to relax, it is a decoration of a summer cottage. Some benches are even used for household purposes. Making a structure with your own hands is a working and at the same time creative process. The result of the construction will delight you for many years.