How to make a reliable bench from a profile pipe

Content

Advantages and disadvantages

A metal bench is a heavy and solid construction, and in material terms it will not be cheap. The metal frame has a number of advantages that justify the price of the product:

- resistance to mechanical damage and strength: neither wind, nor a storm, nor a person on their own can harm the structure;

- comparative ease of installation in front of stone or concrete products;

- resistance to weather factors: not susceptible to the influence of fungi, mold, insects, and treated or painted structures are not susceptible to the influence of precipitation and sunlight.

Among the disadvantages, in addition to the price and heavy weight (compared to a wooden structure), one can also note the difficulties in work that may arise when processing a particular material. However, if a profile pipe is used for the construction of the frame, then these unpleasant moments can be avoided, since the metal profile is easy to process (just welded with a machine), lightweight and affordable. Working with a pipe has its own characteristics, but they can be easily solved with the help of special tools and parts.

Video "How to make a bench with your own hands"

From this video you will learn how to make a comfortable bench for a summer residence with your own hands.

Design options

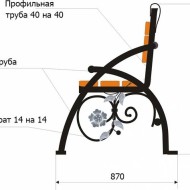

You can make a garden bench from shaped pipes with your own hands, having a detailed drawing and the necessary tools. You just need to decide which one you want: a bench with or without a back, with wooden or forged elements. If you are planning to build a structure of an unusual shape (round, with bends), then for work you will need a bench vise, pipe bending tools and, possibly, a mini-machine "Snail". For conventional rectangular structures - a welding machine and a standard set of tools for working with wood and metal.

An ordinary bench (bench without a back) is not intended for a long rest, it is usually installed near a structure on which you can lean if you want. A fully metal bench with a back is also unlikely to be suitable for a long rest. The best option is a bench with wooden details, but with a frame made of a professional pipe. For decorative purposes, the benches are decorated with forged details. It will be interesting to look at designs with forged lace, animal figurines or imitation of a branchy climbing plant.

How to do it yourself

Most benches made of shaped tubes are made of metal with wooden elements (back and seat). You can make structures without a back and with it at home, but for this you will need the following tools: a welding machine and electrodes to it, a grinder, a drill, a file, a screwdriver, pliers, a hammer, bolts, nuts, nails. As for the materials, the need depends on the choice of the type of bench: shaped pipes, boards, ready-made forged or fabric parts. We will present you with instructions for the manufacture of two types of structures - with and without a back.

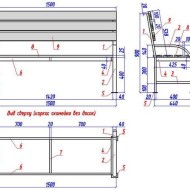

With back

For the manufacture of this type of bench, you will need profile pipes and pine boards. The size and cross-section of the pipes will depend on the size and manufacturing characteristics. For a conventional design, professional pipes with a cross section of 25 × 25 mm (about 8 m) and boards about 3 cm thick are taken. Manufacturing steps:

- Cooking the crossbar. Central lintels are attached at right angles.

- It is necessary to weld bent pipes to the finished part to support the backrest.

- Installation of the front supporting parts of the structure to the workpiece. For greater strength, the blanks of the front supports are welded to the pipe, which will become the transverse lintel.

- Then two arcs are welded between the supports, which are fixed at the base of the legs.

- Grinding of welded seams, priming of the structure and coating with anti-corrosion paint.

- Drill holes for fixing the boards.

- Processing of wooden parts for the back and seat - cover the boards with wood stain or varnish.

- Arrange the boards on a metal blank at equal intervals parallel to each other.

- Fasten the boards using special bolts with round wide heads. For sitting, you need to choose strong thick boards; for the back, you can take a little thinner.

- The decor of the product is chosen according to taste preferences.

Instead of boards or beams, you can use rectangular metal pipes, and for convenience, place pillows lined with leather or waterproof fabric on them. You can also weld armrests for convenience. To do this, you need to bend two pieces of pipe at an angle of 90 ° and weld on the sides. And then process it as a main workpiece.

The boards on the back can be replaced with a beautiful forged part, which also needs to be welded to the main part of the product.

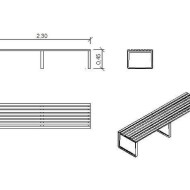

Backless

For the manufacture of such a structure, professional pipes with a cross section of 30 × 30 mm are recommended. The one-piece pipe is divided into the required parts using a grinder.

Adhere to the following algorithm of actions:

- Weld two rectangular supports at right angles.

- Weld the lintels to the prepared supports.

- Sand the seams with a grinder or sandpaper.

- Prime the frame or cover it with protective enamel.

- Drill holes for fastening the wooden parts of the seat. Metal pieces of professional pipes are welded to the main frame.

- Treat boards or seating bars with an antiseptic and stain or varnish.

- Fasten the boards with hardware.

Further work on the product depends entirely on your taste preferences. You can leave everything as it is in its natural form, or you can completely paint the structure with paints or apply patterns using stencils. The all-metal structure can be supplemented with pillows for comfortable rest, which can also be made by hand. So that your beautiful bench does not make others want to borrow it without asking, it is better to fix it. If there is a nearby fence, supports can be welded to its base. Also, the supports can be bolted to the bases, which are placed in boreholes and concreted.