Construction of a spacious hexagonal gazebo with your own hands for the whole family

Content

Calculations

Before starting construction, it is necessary to plan from what material, in what place and what size the new building will be. Usually gazebos are built of brick, wood and metal. By design, such buildings can be open, closed and semi-open. The latter is more popular due to its practicality.

Having determined the material of the future structure, we proceed to choosing a place on the site. For this purpose, a small flat area away from the main dwelling is best suited. The presence of green spaces or proximity to a reservoir will provide the future building with coolness on a hot summer day.

Now it is important to determine the size of the gazebo. First of all, it will depend on the number of people who are supposed to be in it. It is also necessary to consider the possibility of installing furniture and barbecue.

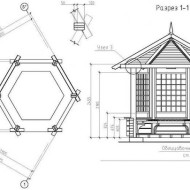

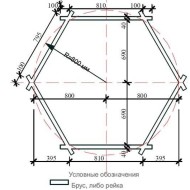

After determining all the initial data, it is important to make a project, the main component of which will be drawings or sketches of the gazebo and the calculation of its individual elements. Now let's take a step-by-step look at how to build such a gazebo yourself.

Video "DIY hexagonal gazebo"

In this video, you will learn how to build a hexagonal arbor from wood with your own hands.

Construction of a wooden structure

Wooden gazebos differ from buildings made of other materials in their aesthetics and environmental friendliness. The use of timber makes construction cheaper and more convenient for the installation of various structural elements.

The disadvantage of such a gazebo is the ability of the tree to collapse under the influence of precipitation. In addition, wooden structures are more fire hazardous than those made from other materials.

To make such a gazebo, you will need the following tools:

- shovel;

- rope, pegs;

- plumb line, building corner;

- measuring tool, rule with level;

- a hammer;

- hacksaw, jigsaw;

- chisel;

- screwdriver or screwdriver.

Before starting construction, it is important to determine the type of timber that will be used in the construction of the structure:

- profiled;

- glued;

- rounded.

After fully determining the size of the gazebo, its place and material, we will start construction.

Step-by-step instruction

- Let's mark the selected site for the device of the strip foundation for the wooden gazebo.

- We will dig a trench 30–40 cm deep and about 30 cm wide. Install the formwork along the trench so that the surface of the foundation is 10–15 cm higher than the ground.

- We reinforce the inside and fill it with concrete. We will provide for fastening the foundation with the lower frame of the building in the form of pins or strips. Then let the skeleton dry.

- Install the lower frame beams on the foundation and rigidly fasten them to the frame.

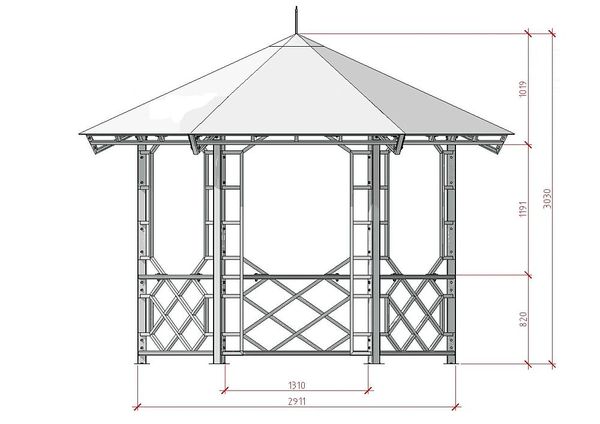

- With the help of lamellar metal corners and screws, we put vertical logs and connect them with horizontal partitions.To increase the rigidity between the vertical posts and the horizontal components of the structure, we install gussets between them at an angle of 45 °.

- We will strap the upper frame for the future roof structure. With a small gazebo, the roof frame is assembled on the ground. Then the assembled rafter structure is lifted and sheathed at the top.

- We will assemble a six-slope roof truss system from a previously prepared timber. For the B-pillar, you need to make a wooden hexagon. It is on this beam that all the roof ridge will rest. When assembling the rafters, the angle between the skates should be controlled. It should be 60 °.

- We cover the roof with roofing material provided for by the project.

- The floor of the gazebo is made at various stages of construction. Let's put it together. We will install the logs, resting their edges on the inner surfaces of the foundation, fasten them to the lower frame.

- We will sew the floor with a special floorboard profile. It is important that the floor does not bend. To avoid deflections of the lag in the middle part of the gazebo, columnar foundation supports are made.

- We trim the side surfaces of the gazebo and install decorative elements.

- We will process the surface of the building with varnish in several layers.

After the varnish has dried, we arrange the furniture and enjoy our own wooden creation.

Erection of a metal building

Arbors made of metal have a special refinement of their forms. Forged artistic ornaments, which are used to decorate such structures, add lightness and unforgettableness to the country structure. The main advantage of such a structure is fire safety and reliability. The disadvantage is the periodic need to paint some elements or the entire structure.

Such a gazebo can be purchased ready-made, but not all residents of summer cottages can afford it. For self-production you will need:

- shovel;

- hammer, hacksaw;

- measuring tool;

- pegs, rope;

- Bulgarian;

- welding machine.

The main scope of work

- Let's mark in the planned place the outline of the future gazebo. At the corners of the hexagon, we will dig holes 30 × 30 cm, 40-50 cm deep. Another one - in the center.

- We will make a formwork for each post. Fill the pillars with concrete. The upper plane of the posts should be 10-15 cm above the ground.

- Remove the formwork and let the foundation dry. When pouring in corner posts, it is necessary to provide for the possibility of rigid fasteners with a lower strapping.

- For the manufacture of a metal frame, we take square shaped pipes and weld them in accordance with the drawings and diagrams. With the small size of the gazebo, the entire structure can be made separately, and then installed on the foundation. If the building is large and inconvenient for transportation even on site, then we cook directly on the posts.

- Racks, upper frame, rafter system are welded into a single element. It is important to comply with the dimensions of the perimeter of the structure so that it exactly stands on the foundation.

- After installation on the foundation, rigidly fasten the structure frame to the frame.

- Weld all design elements of the interior wall space, including forged products.

- On metal logs that rigidly connect the opposite sides of the lower frame, we install a floorboard.

- We cover the roof with the material that is installed by the project.

- We degrease and paint the created structure in the desired color.

The gazebo is ready!

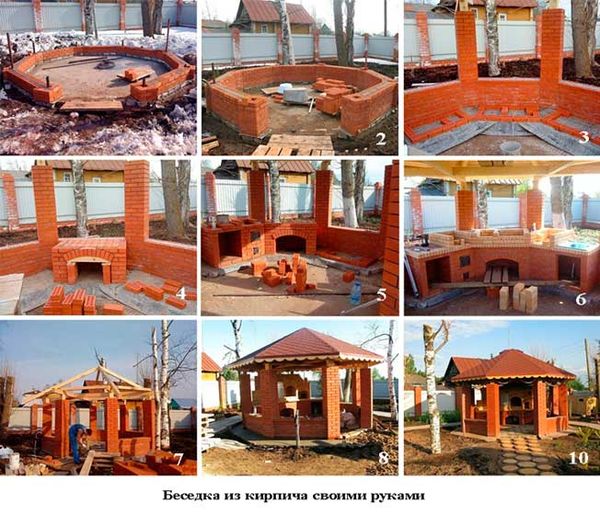

Brick analogue

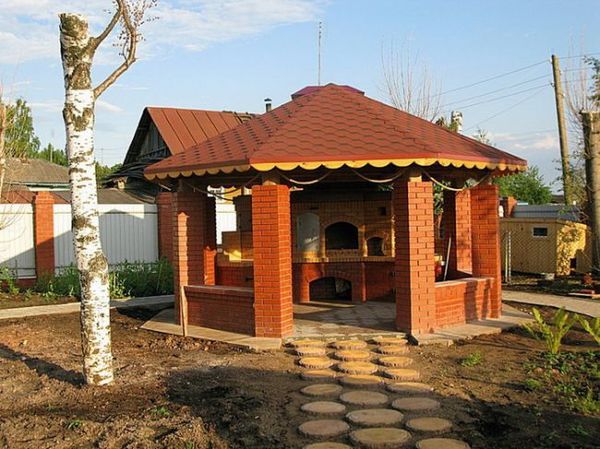

The hexagonal structure can be made using bricks. This material will add monumentality to the structure and allow more complex projects to be realized. A built-in oven or barbecue maker will be appropriate when erecting such a structure. The reliability and durability of brick gazebos has no expiration date.

To complete the work, you will need the following tools:

- rope with pegs;

- shovel, hammer;

- measuring tool;

- Master OK;

- carpenter's set.

Construction technologies

The execution of a brick gazebo will differ significantly from structures made of other materials. Let's take a closer look at this process:

- Let's mark a site for a monolithic foundation. This type of foundation can easily withstand the load of a brick structure, especially if it is with a barbecue. In addition, such a foundation will be a ready-made subfloor - without finishing.

- We will dig a pit to a depth of 40-50 cm. The area of the pit should be slightly larger than the perimeter of the future building. It is important to correctly measure and calculate the contours of the future gazebo already at the initial stage.

- Cover the bottom evenly, first with gravel, and then with sand to a level of 10–15 cm. Level the surface and install the formwork.

- We reinforce the inner cavity of the pit using various unnecessary metal profiles.

- Fill the foundation with concrete 10–15 cm above the ground. Let's let the skeleton stand as long as possible (up to 3 weeks).

- After the foundation has dried, we will proceed to laying the stove or barbecue provided by the project. The device of the furnace equipment is made of red brick, and the combustion chambers are made of chamotte. When building a barbecue or smokehouse, those walls that are subject to strong heating are laid using a clay-sand mixture, which is prepared in advance from clay. This avoids the appearance of cracks during the operation of the furnace equipment.

- Let's start building the walls. Usually white silicate or red brick is used for these purposes. First, we will erect pillars in each of the six corners. They are made in widths of a brick or one and a half.

- We lay the walls in half a brick, measuring each corner of the future hexagonal structure. It is better to make a template for this in advance.

- In accordance with the project, we lay blank walls and leave the space that should be hollow open from the window line to the ceiling. These parts can be used for glazing. The gazebo will be transformed and become a summer kitchen.

- From a previously prepared timber, we collect the beams of the upper frame, which will become the support of the future roof.

- Cut out the skates for the roof and connect them in the middle with a central hexagonal post.

- We will sew the roof with the design roof covering.

- Let's start finishing the floor. Tiles work best for this job.

The construction of the brick gazebo is ready, we proceed to the design and furnishing of the interior.

Any of the considered designs will decorate the summer cottage. A brick gazebo will be less whimsical in maintenance and care. Metal structures require periodic painting. Wooden also requires constant attention to the condition of the varnish coating.

Maintaining a satisfactory appearance and normal condition will not take long. And the huge amount of positive emotions that the new building will allow to receive will make caring for it exciting and interesting.