Terrace railing: classic and modern railings

Content

Purpose of the structure

The main reason for installing handrails is the need to limit the free space of the veranda or terrace. Flooring is always above ground level and building codes require fencing of elevated areas. The main entrance is equipped with one or more steps, and the rest of the openings need to be set.

In addition to its restrictive function, railings can protect from the wind and make the building more attractive. The design of the railings emphasizes the stylistic orientation of the terrace design.

Video "Railing for the terrace and the method of their fastening"

In this video, you will learn which railing is suitable for a terrace and how to fix it.

Variants

Before making a fence with our own hands, let's figure out what types of railings are:

- open, intended mainly for decorative purposes;

- closed, allow you to protect the structure from the wind and prying eyes.

The choice of the material of the railings depends on the design of the house, next to which they are installed.

Metal fences are made using forged patterns, which are distinguished by their lightness and gracefulness. The use of steel profile pipes makes the railings heavier and more conservative.

The use of tempered or laminated glass will make the fence invisible, but at the same time functional. Transparent cellular polycarbonate will perform the same tasks, but will cost significantly less. Its application will simplify the installation of structures.

Railings in the form of stretched metal cables or ropes will add a nautical mood to the deck of the building. Fencing with bamboo or reed will make the terrace exotic.

Modern technologies allow the use of synthetic materials. Installation of ready-made polyvinyl chloride (PVC) structures will reduce the cost of the railings. Plastic structures are not very durable, but do not require maintenance.

Fences made of wood-polymer composite are more durable and demanded products. This material outwardly resembles a wooden structure in a light or dark shade, it is highly durable. The presence of synthetic additives allows you to maintain the shape and color of the structure, regardless of environmental influences.

Stone railings are installed only on monumental buildings, which are very rare today.

The leading position in the manufacture of handrails is taken by structures made of wood. The unique variety of shapes, the availability and low cost of such material make it possible to use it much more often than other materials. The need for constant maintenance is a big disadvantage, but it cannot hinder the ease of making wooden fences.

DIY wooden fence

Before manufacturing, we will select the type of wood for the railings. It will be undesirable to use ash, maple, since the structure of the fibers of these rocks will quickly collapse when used in an open area. Choosing oak or Siberian larch, we will provide the structure with durability, reliability and beauty.

Pine is usually used for the manufacture of fencing, which has a low cost and is convenient for processing.

To work, you need the following set of tools:

- hacksaw, jigsaw;

- measuring devices;

- screwdriver;

- plane, ax, chisel;

- Sander;

- woodworking machine in the manufacture of balusters.

Then follow the following algorithm of actions:

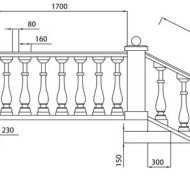

- Before starting work, we will make a drawing, which will indicate the dimensions of the sections, the shape of the supports and balusters.

- We prepare the timber by calculating the required number of sections. Wooden beams must be dried so that after cutting and installing the railings do not lose their shape. We grind all structural elements before assembly.

- We install the supports through the conditional 1.5 m. In order for the fence to have an attractive appearance, we correct and make these distances the same. We take into account the possibility of using the vertical posts of the terrace as supports for the fence.

- We assemble the railing sections using wood glue, tongue-and-groove joints or using screws.

- We begin the assembly from the corner or adjacent to the main structure of the supports. Having connected the section with the support, we install the assembled structure and attach it to the flooring. We use lamellar corners with screws as fasteners. It will be more technologically advanced to use hidden fasteners of the fence posts.

- Let us prevent the inconvenience of installing the last section of the railing. To do this, fasten the penultimate support to the flooring is performed last, this is especially important when using vertical terrace posts as fence supports.

- After assembling the entire structure, it must be varnished or painted.

Support

For the manufacture of supports, we choose a wooden bar with a square section of 150x150 mm. This size will allow you to withstand heavy loads, will make it possible to lean on it and on the installed section, which will be attached to this support. If the railing is made exclusively for decoration, then the cross-section of the beam may be of less importance.

We make the height of the fence posts 1 m. This is the standard size for such structures. The support can be made in the form of a pillar with straight surfaces or in the form of a carved structure, while it is important not to forget about the necessary strength of the part. On the sides of the rack we cut out the grooves for fastening the spikes of the horizontal slats of the sections.

Railing sections

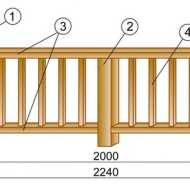

There are several types of sections:

- horizontal - when most of the rails are installed parallel to the flooring;

- vertical - made of balusters fixed between the upper and lower rail;

- cross - in such sections, the slats of the same section intersect with each other at different angles.

The use of each of these types of construction is largely due to the type of material. For wooden railings, the most suitable and familiar is the production of vertical sections.

When making sections, balusters can be made by yourself. This will require a small woodworking machine. The absence of a machine will require the use of a conventional square or rectangular bar. As an option, it is possible to purchase ready-made balusters, the size and shape of which are varied. They are widely available in retail.

For the assembly of vertical sections, we will prepare horizontal slats. At the ends of the rails, we will make spikes for connection with the supports and make markings for the installation of balusters. Using the screws, twisted in a secret, we connect the vertical decorative racks with the horizontal slats. After assembling all the necessary sections, we proceed to the installation of the railing.

Treatment

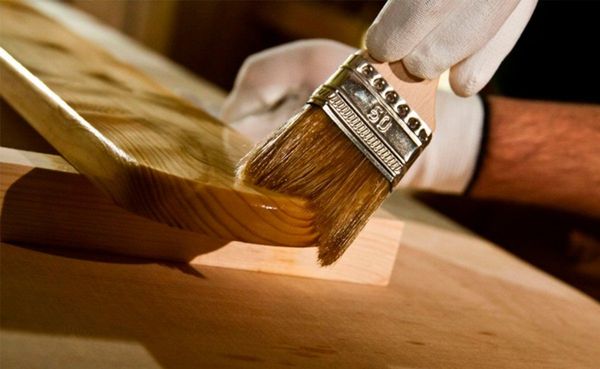

Before using each piece of wood, it must be sanded to obtain the desired shape and surface roughness. After assembling the individual elements into an integral structure of the terrace railings, we identify the places that require additional finishing.These can be both flaws before assembly, and the consequences of unevenness in the connection of joints. We eliminate the identified shortcomings using a grinding machine.

Wooden structures that are used outdoors are susceptible to rainfall and small pests that can destroy the internal structure. To prevent this, we impregnate products from a bar with an antiseptic, which is able to resist the destruction of the material. After drying, we apply several layers of varnish or paint in accordance with the project.

Using different colors when painting fences allows you to give a different shade, and, if necessary, highlight the main residential structure or the railings themselves.

After isolating our terrace with wooden structures and decorating them in the desired style, we can feel the fullness of the comfort of the terrace. Then you can invite loved ones to confirm your own feelings.