Delicious food with a smoke: building a fireplace in the country

Content

Varieties

Depending on the design, the hearths can be divided into stationary, portable, buried and outdoor versions. These structures can take various forms:

- rectangular;

- square;

- round.

The latter is the most popular due to the ease of cleaning the inner surface and the increased cooking possibilities.

According to the material of manufacture, the foci are divided into the following types:

- stone;

- brick;

- metal.

Video "Hearth for a fire, made by hand"

In this video, you will learn how to make an outdoor fire pit with your own hands.

Building rules

Regardless of the design features and the material from which the construction for the fire will be made, it is necessary to go through all the stages of work:

- Determination of the place for the fire. It is important that it is away from other buildings at a safe distance. Smoke and sparks from the fireplace should not reach the buildings of the suburban area.

- The choice of material. The solution to this issue is influenced by the desired appearance and availability of the material.

- Execution of design work. Includes solutions for the design features and dimensions of the future hearth.

- Base device.

- Wall masonry or production of a metal case.

Do it yourself

The process of making a future campfire site is available to any summer resident. Everyone can equip a hearth on a personal plot with their own hands.

To complete the work, you need to prepare in advance the material from which the construction is planned. The production of the base is possible in the presence of sand and cement. The following tools are needed to solve the problem:

- shovel;

- measuring devices;

- trowel, spatula;

- welding machine for metal structures;

- drill with a special stirring attachment.

Of stone

To make a hearth from a stone, you must perform the following work:

- Mark the selected place for the installation of the structure. It would be better to lay out such material in a circle, the outer diameter of which is from 1 to 1.5 m.

- The top layer of soil is removed with a shovel to a depth of 15–20 cm. After that, the surface must be cleaned of weed roots.

- Next, you need to mark the inner contour of the structure and pour a concrete base under it with a height of 10-15 cm. The inner diameter is designated so that it is possible to make an internal brickwork with a small gap from the external stone masonry.

- After the frame has dried, we lay out the inner contour of the hearth with fireclay bricks, using the order. In order for the inner diameter to have a clear round contour, it is necessary to hammer the reinforcement in the center of the hearth. A rope is used to control the inner radius when laying refractory bricks. Keeping the same distance on all sides will allow you to get the inner cavity of a round shape.

- The height of the inner masonry must be made 15 cm less than the design size of the hearth. For laying refractory bricks, a sand-clay mixture is used, which will not crack at high temperatures.

- Maintaining the gap, it is necessary to lay out the external natural stone masonry to its full design height. The gap between the masonry is covered with heat-resistant material. Usually they use quartz sand with glass or fine gravel.

- The upper part of the inner masonry and the gap are laid with the same material from which the outer masonry is made.

- For safety, the area around the hearth must be paved with any materials that are safe in case of fire. This can be crushed stone or brick laying.

The outdoor hearth is ready, it remains to pick up a grid or grate of the appropriate diameter in order to cook a fragrant dish on the fire.

Brick

The construction of a brick hearth differs from a stone one in the exclusively used material for external masonry. You can use white sand-lime brick, but red is better. The latter has thermal insulation properties. This quality will allow you to enjoy the iridescent tongues of the fire of the garden fireplace for longer.

As in the stone version, the internal masonry is made of fireclay bricks on clay mortar. The height of the hearth is 60–80 cm above ground level. The external brickwork is done with a regular mortar with a little lime added. The gap between the masonry is covered with heat-insulating material.

The original shape will differ from a square or rectangular hearth. When using bricks for the outer surface, the correct outlines will be emphasized by straight lines of the masonry.

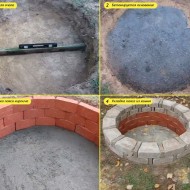

In the ground

Arrangement of a structure in the ground will have slight differences from a stone and brick structure:

- The soil of the future round building must be removed to a great depth - 40-60 cm. In this case, the diameter of the pit should exceed the size of the inner masonry by 7-15 cm.

- After excavation work, you need to pour crushed stone of the fraction to the bottom (20-50 mm) and compact it tightly.

- Using the central post, line the inner cavity with refractory bricks and clay mortar.

- Fill the gap between the masonry and the ground with rubble. Lay with red bricks flush with the ground or with a slight rise.

- The bottom is best covered with a round metal sheet for any design of hearths. This will allow you to effortlessly clean the inner surface of coals and ash.

Metal bowl

A garden with a hearth in the form of a bowl will be fabulous and unique.

For self-production, you will need a part of a metal sphere, hollow inside. This form is difficult to find. You can use a sheet of metal with a thickness of 2-4 mm, cut a large circle, then cut from the edges to the center to half the length of the radius and bend the edges at an angle of 20-40 °. You will get a bowl that needs to be equipped with legs and set in a safe place. It is recommended to paint the finished product with fire-resistant black paint. With little effort and no cost, we get a portable hearth.

Concrete

Making a concrete structure will require a lot of effort, but in the costly part it will not go far from a metal bowl:

- Depending on the desired height of the future building, it is necessary to dig a hole. Considering that the manufacture of round formwork can cause great difficulties, the concrete hearth is made in a square shape. Accordingly, the pit will have the same contour.

- The base is covered with crushed stone, then leveled.

- After that, you need to make the formwork of the contours of the outer and inner walls. The width of the future concrete structure will be 30 cm.

- Internal cavities are reinforced and connected with metal profiles and nets.

- It is necessary to pour concrete, let it grab and remove the formwork.

- After the walls have dried, a metal container is installed in the inside and sprinkled with rubble or pebbles on all sides.

- The surface of the concrete walls is covered with decorative tiles or other finishing materials.

Decor options

The design of the source of open fire should be performed using fire-resistant materials.Using a ready-made area for evening gatherings will require the manufacture of a hearth in the style inherent in the selected area. This can be the exterior finish of the fire source with the same material that was used in the construction of the site.

Installing a fireplace in a new place will require creating a cozy environment around it, corresponding to the landscape design of a suburban area. An example of such a design would be the arrangement of benches around the fire. The decoration of the hearth and the resting places should be harmoniously combined.

After completing all the work, you can sit in your favorite garden near the fire, without taking your eyes off the playing tongues of flame. Using a metal mesh that can be used to cover the hearth will allow you to cook meat or fish with a pleasant smoke smell. And to prepare more serious meals over the fire, you need to set up a tripod. Hang the pot or cauldron with a hook and chain. Now you can cook kulesh and talk about life.