How to build a brazier with your own hands: instructions from professionals

Content

Typical varieties

Simplified designs in the shape of a square are held in high esteem by 75% of summer residents. The main material here is metal, from which strong legs and body are obtained. Such devices are easy to clean, and due to the good thermal conductivity of the base, they contribute to juicy frying of meat.

Homemade types of barbecues are characterized by unusual shapes and sizes. It could be a small suitcase with a niche for coals and wood chips. Supporters of the most original designs will certainly be interested in sketches of products in the form of steam locomotives or ships with masts. Special attention should be paid to:

- Stationary models made of stainless steel and brick. They do not fade or deteriorate under the influence of moisture, but due to their static position they remain unbreakable.

- Portable versions with wall thicknesses from 1 to 3 mm. The simplest devices are devoid of side surfaces and bottom, which complicates the preparation of barbecue. It is better to use more powerful units with a black steel base. They are equipped with small handles for easy carrying over long distances.

- Dismountable structures with height adjustment with minimal dimensions ensure high-quality cooking at home. They can be installed anywhere on the site.

- Mobile barbecues with coasters for the cauldron cannot be disassembled, but thanks to durable castors, they can easily move around the veranda.

- Modern electrical installations on spirals, in particular barbecue makers, promote uniform heat treatment of products. With an electric motor, gears and a drill, such a project can be implemented independently.

To smoke boiled pork you need a grill with a roof. And so that the walls of the buildings do not become overgrown with soot after each culinary experiment, you will have to consider more practical models of units with pipes.

Video "Brick brazier, made by hand"

From this video you will learn how to build a brick brazier with your own hands.

What can be done

A properly constructed chimney significantly reduces the likelihood of fires in gazebos with barbecue. The work is supposed to use refractory bricks. Unlike silicate ones, they heat up and cool down 3 times faster, and due to their high heat resistance, they retain their operational properties even at 1500 ° C. For laying the base, ordinary red brick marked M-150 is suitable. It contains almost no cracks and does not crumble. If you need to sheathe the firebox, you will need fireclay products of a uniform color.

Self-production of a barbecue according to the scheme also provides for the use of metal sheets, fittings and corners. First you need to weld the rectangular coal block and the supporting elements of the structure. Then prepare a removable stand, and most importantly, a solid base for the unit. To lay the foundation, you will need M-400 cement, river sand, clay, metal rods, bricks and dried formwork boards.

When constructing professional installations with a double bottom, special plates are needed for better fuel ignition. Efficient ash cleaning will be provided by wire staples. When drilling holes in the walls, it is important to follow the drawing data. This will help to avoid technical errors and, as a result, unreasonable costs.

The working process

In 35% of cases, the choice of basic materials depends on the types of summer extensions. For example, for completely enclosed structures, you will need natural stone or fireclay bricks. In the absence of side walls or even battens, stainless steel options should be discussed. The most beautiful barbecues in the form of fairy-tale characters and animals are framed with forged elements. You can make them yourself or order ready-made arcs, friezes and curls on the Internet.

From the tools you will need a drill and a grinder. For finishing structures - stationary saws and band saws. Scissors for metal with a power of at least 450 W will allow you to cut a sheet with a thickness of 1.5 mm. If you need to cut off a piece of pipe or fittings, use a hacksaw. It is better for inexperienced specialists to rent gas welding equipment with personal protective equipment.

Stationary

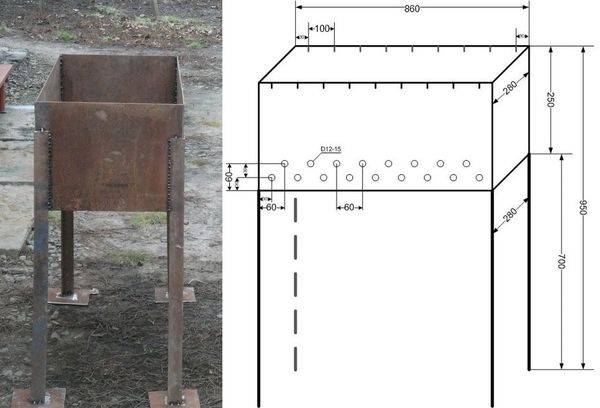

Powerful cast iron devices are the best option for the street. You just need to pick up sheets with a thickness of at least 3 mm. Then we act according to the scheme:

- We mark the base in accordance with the drawing plan.

- We cut out the side walls and the bottom.

- We drill holes for better coal combustion. If this is not done, the fire in the grill will have to be fanned with improvised means.

- We process the bottom of the tank with an angle grinder.

- We drill recesses for skewers at a distance of 3-4 cm from each other.

- We fasten the rectangular box with a welding machine and clean the seams.

- We weld the legs made of metal rods to the finished structure.

If time permits, you can make a brazier in the form of a regular quadrangular prism. This will require a little more materials and patience. At the end of the main work, the structure should be treated with a heat-resistant coating. We are talking about powder compositions that increase the metal's resistance to corrosion. They are not thixotropic. But they can withstand abnormally high temperatures well.

Folding

The presented model is ideal for those who like to relax in the woods and mountains. The optimal thickness of the structure varies from 3 to 4 cm. In the choice of materials for the bottom device, it is better to prefer 3 mm steel sheets. They withstand high temperatures and mechanical stress well. The size of the barbecue depends not so much on the quantity as on the thickness of the skewers. Ideally, this figure is 75 cm.For frequent trips out of town, you will need a lighter 40-centimeter unit.

To prevent the structure from folding spontaneously, a hook must be attached to one of its surfaces. Support elements should be welded to the legs, and then the grill will not dig into the ground. The short walls of the device must be removable. They are attached to the bottom with clamps. Awnings must be installed between the base and the side surfaces. This is a prerequisite for the folding mechanism to function.

Collapsible

For the base of the barbecue, solid sheets of steel are needed. The frame should be made of pipes with a diameter of 18 mm. Other materials will require grates, bolts and nuts. The optimal length of the structure is 70 cm, and when folded it is no more than 40 cm. First, the owners need to mark the base. This can be done with a building ruler, tape measure, and pencil. When using cardboard templates, the probability of technical errors at this stage is reduced by 5 times.

Angles or canopies should be used as attachments. Sections of finished parts need to be sanded, and holes for handles should be made at the ends of the device.Then we fix the legs and process every detail of the structure with protective compounds based on porcelain stoneware.

Collapsible barbecues need regular cleaning. After roasting the meat, they should not be sprayed with cold water. To prevent the metal from spoiling, the brazier must cool naturally.

The easiest option

An elementary brazier without a body can really be made of metal sheets with a minimum thickness. In the work, 4 corners corresponding to the dimensions of the installation, and support posts are useful. In good weather, installation takes only a few hours. Homemade designs look pretty simple, but, unfortunately, they do not contribute to:

- uniform frying of meat products and vegetables;

- simultaneous preparation of several dishes at once;

- good ignition of coals;

- prolonged use of the device in the open air.

If the main raw material is brick, it is imperative to make a cutaway drawing of the barbecue. Then lay the foundation, build a basement row, chimney and canopy. The work will take 5-7 days, but this is the best that can be offered to connoisseurs of high-quality products.

Tasteful decoration

Elements of artistic forging are able to revive even the most ordinary-looking construction. These include decorative stripes, curved posts, cast iron rosettes and curls. If they are correctly fixed, the side surfaces of the barbecue can take the form of a small rocket or a ship with a deck. And since the metal sheets bend well, the brazier can even be made zigzag. Home-made units in the form of chests, boxes and military equipment are especially popular among consumers.

The natural stone stove complex should be additionally sheathed with porcelain stoneware. This will not only improve its appearance, but also increase the resistance of the barbecue to the weather.

Original ideas

It is incredible, but the brazier can even be constructed from the body of a car. For creativity, rare cars that have long been out of order will come in handy. As an option, you should consider models from tires, system units of office equipment and shopping carts.

Luxurious animal-shaped items are obtained from barrels. In this case, it is possible to combine several materials in one device at once: cast iron, wood and refractory plastic. Old gas cylinders can become the basis of a smokehouse and smoker grill.