Barbecue from a gas cylinder: a master class on making a barbecue

Content

Features and Benefits

A brazier from a gas cylinder, despite the pragmatic design, has its own characteristics. There are several types of hearth for frying, the main thing is that each of them can be built with your own hands.

Types of stoves:

- a simple barbecue without a lid;

- B-B-Q;

- smokehouse;

- smoker.

Braziers are built from propane and oxygen cylinders. These designs are the ideal basis for the creation of various products. The cylinders are made of high quality metal, in the right shape and with optimal dimensions. This makes it as easy as possible to create a cooking hearth. At the same time, it is possible to save on material and reduce the time of work.

Gas cylinders have thick walls, due to which they perfectly withstand high temperatures. Thanks to this, they are a good base for a grill, smokehouse, grill, etc.

Metal container:

- does not burn out even after prolonged use;

- has thick walls, optimal configuration;

- multifunctional;

- easy to operate;

- unpretentious care;

- affordable;

- easy to install.

The disadvantages of such a barbecue maker are at least. Users highlight the significant dimensions of the capacity as an inconvenience. But there are also compact options on sale. Professionals note that the semicircular bottom is not very convenient when firing up. Also, a brazier based on a cylinder is quite heavy, it is impossible to transport it alone.

Video "Brazier from a gas cylinder in three hours"

From this video you will learn how to make a brazier from a gas cylinder with your own hands in a few hours.

Preparatory work

In order for a homemade frying hearth to be effective, and you made a minimum of mistakes in its manufacture, you need to prepare for the work process. The main assistants are welding and grinder.

We select a gas cylinder and proceed to its preparation. It will be useful to draw up a design project, which will also help in calculating building materials. Any cylindrical balloon can be used for the barbecue. The classic version is a 50 liter container. If a more mobile barbecue is a priority, a standard 27 liter cylinder will do. Some containers are distinguished by an increased diameter, which significantly increases the efficiency of ignition. Due to its large size, the width of the container optimally accommodates several skewers.

From the tools we will use welding, grinder, electric drill, tape measure, core, wrenches, etc.

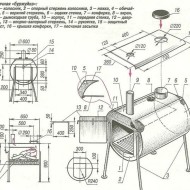

Drawing

Drawing up a project of a barbecue from a gas cylinder will not take much time. It is quite enough to create a simple drawing, in which it is necessary to indicate the dimensions of the structure. Thanks to the developed scheme, you will determine the required amount of material, correctly plan where the functional components will be located.

Experts say that detailed planning is the key to successful construction.

Step by step instructions

Making a brazier yourself is not so difficult. It should be remembered about safety precautions, because there will be cutting of the product in which there was gas. Avoid sparks, ignition of propane residues.

The first block of works:

- We turn off the valve, the remaining gas should leave the container.

- We turn the structure over, wait for all the condensate to leave.

- When no bubbles appear, proceed to the process.

- We fill the vessel with water, drain the liquid after a few hours.

- We put the container on one side, cut off the valve. Treat the saw cut with water.

Having coped with the first block of work, we proceed to cutting and welding the components.

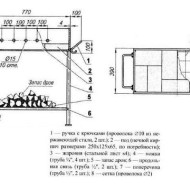

Marking, sawing

Usually a kebab maker is made on the basis of a 50-liter propane tank. This allows you to cook about 6 portions of kebab. Since products of this type can be called standard, their markings are considered uniform. If you wish, you can find a smaller design.

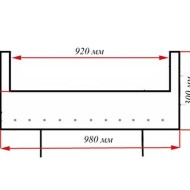

The outer diameter of the container is 96 cm. We divide it into 4 parts, it turns out 24 cm. The marking is carried out along the longitudinal seam. We measure all distances from this line, which will ensure the evenness of the marking and the absence of distortions. We measure 24 cm from the seam on both sides, draw lines. We put the product horizontally. Make sure the seam is at the bottom. We make markings for skewers.

We find circular seams, measure 3 cm from them. We do this on both sides. Then the marks are applied every 8 cm. You should get 6 points, in them we make holes with a diameter of 1 cm. Now the marking of the lid. Consider the first marked line and the last. Apply a strip between them 3 cm from the circular seam. The lid is finished.

The next step is sawing. You need to divide the container in half. We will perform the operation along the weld. Do everything carefully. Use the tool closer to the seam. We do not touch the side walls, they will function as a fire damper and maintain the optimum temperature. When cutting, keep the side rings intact - this is the support for the cover.

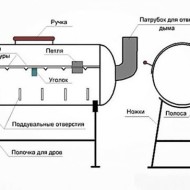

Assembling the elements

Often, during the operation of a barbecue, its deformation is possible. To prevent this, we weld the corners inside the longitudinal edges. Due to this, a protrusion is formed, where a rasp, skewer is conveniently located. High legs must be additionally well fixed. For this, a welded corner from the outside is also suitable.

We make holes in the bottom of the container. This will make it easier to pour out coals, draining water after a rainstorm. Plus, such holes will provide traction, which will have a positive effect on the combustion of solid fuel.

At the place of the valve, by welding, we install a pipe for removing smoke. Make it yourself or buy the assembled one. Many users do without a chimney, you can do this too if you are going to cook food with the lid open.

Creation and installation of handles and legs

It is necessary to decide how high the brazier will be from a standard propane cylinder. Then we fasten the legs. The structure should stand firmly, plus it will be more convenient to weld the lid.

Bolts are suitable for securing the handle. We drill holes for them, fix them. The best option is simple, high temperature resistant handles. Sometimes they are made on their own using metal rods. We weld the handles to the base. We mount a limiter on the cover, which is created from the corners or pipe components.

Decorating

In order for the grill to serve not only as a functional component, but also to please the eye, its final finish plays an important role. Today, you can emphasize the type of structure in absolutely different ways - from ordinary painting to the application of forged parts.

The shashlik maker in the form of a steam locomotive looks unique. Do not confuse with a separate type of hearth for frying - "smoker". However, only specialists with welding can do it on their own.

Barbecue painting

If an old cylinder was taken as a basis, you cannot do without painting it. Processing can be done with different materials, most often they use:

- silicone heat-resistant enamel;

- powder thermal paint - needs to be fired in an oven;

- oxidation - reliable protection against corrosion.

We strongly recommend processing the grill, since iron is oxidized and rusts. The special material will extend the life of the container.

You need to cover the surface evenly. It is advisable not to be limited to one layer. After the initial treatment, take a break, letting the paint dry. It is better to start frying on the grill 7-10 days after painting it.

How to make an oven with a smokehouse

The smokehouse differs from the usual barbecue by the presence of a firebox. Therefore, the tightness of the structure is a priority. To create such a stove, you need to remove half of the bottom. The firebox is formed from iron sheets. Previously, a different cylinder was used for this, but the design turned out to be too overall. Parts are welded, a chimney is equipped. It only takes a couple of steps to turn a traditional barbecue grill into a smokehouse. The main thing is to make sure that the stove is airtight and the chimney is reliable.

You should not start cooking on the grill immediately, but after a while. If you have processed the structure, it is better to wait 7-10 days until the paint is completely dry, its smell will go away. First, fire the hearth with wood. If the smell of gas has strongly eaten into the walls of the container, the structure must be heated several times.

It is known that the most beautiful and reliable barbecues are made of bricks, but a construction from a gas cylinder, erected correctly, will be no less effective. Paying attention to its decoration, you will get a worthy decoration of a summer cottage at all.