Fast, simple and unusual: barbecue from an iron barrel

Content

Benefits of a metal brazier

The main advantage of using a barrel is its spaciousness. A lot of fuel is placed inside, which is quite enough until the end of cooking.

In addition, there are other benefits:

- Easy care. The metal is quickly cleaned of stains and combustion products, it is easy to patch it up in case of breakage.

- Mobility. The device does not pull your hands when carrying, easily fits into the trunk of an average car.

- Stability. The kebab maker stands firmly on the supports, does not topple over by the wind or from an accidental shock.

- Safety. The metal does not burn, so there is no danger of sudden ignition.

- Cheapness. A self-made construction will require minimal financial costs.

However, do not forget about such a lack of metal as the ability to rust. When it rains, it is better to put the device under a canopy, and at the end of the summer season, hide it in a dry room. Another disadvantage is fast heating. Being near the barbecue, you should be careful, otherwise you can get burned.

Video "Brazier from a barrel, made by own hands"

This video tells you how to make a grill from an old metal barrel yourself.

What capacity to choose

Choosing from barrels of different capacities, we recommend sticking to 200-liter ones. These are usually used to store alcohol, paint or solvent. The barrel must be made of metal - wood and plastic are not suitable for working with an open flame.If you need a smaller option, you can take a 60 liter barrel of fuels and lubricants.

Since the container will have to be cut, it is advisable to immediately secure the process by removing all possible accumulated gases. For this, the barrel is filled with water and then emptied immediately. Next, the container is left to bask in the sun.

In addition to the basics, you will need additional materials:

- diesel fuel;

- high temperature resistant paint;

- steel corner with shelves 2.5x2.5 cm;

- metal strip 25x10x1.5 mm;

- profile pipe of square section 1 m high.

Manufacturing technology

To work you need tools:

- grinder and grinding discs;

- welder;

- electric drill with a set of drills;

- spray gun;

- marker and tape measure.

The construction of a homemade barbecue is simple. The barrel is cut into two parts: one half turns into a brazier, the other into a lid (however, you can do without it). Both parts are fastened with steel door hinges, metal legs are made from below. The combustible fuel collects at the bottom. It is advisable to mount the cover to protect it from the wind during the cooking process, it will also protect the device from precipitation.

Whichever option you choose, be sure to sketch out a detailed drawing of the future design. Careful preparation will save you many of the hassles that often arise during the work.

Open model

If you make a brazier without a lid, the scope of work is reduced. First of all, it is advisable to immediately make a stand for the barrel - a frame structure with racks.

The barrel is cut according to the following scheme:

- The surface is cleaned of paint using a grinder.

- Mark a longitudinal line with a marker, cutting the cylindrical structure strictly in half.

- With the help of a grinder, a cylinder is sawn. You need to work in goggles and protective overalls. Saw against the rotation of the disc so that the tool does not "bite" by the metal.

- The edges of the sections are sanded, getting rid of burrs.

- For the half that forms the future brazier, they make a metal edging from the corners. Measurements are made from all sides, corners are cut, then a rectangular frame is welded.

- Legs are made from shaped pipes. One of the ends of each leg is cut at an angle of 15 ° to give them a slight spread.

- The legs are welded to the edging with the cut corner up. In order for the pipe to fit snugly against the barrel, edges of the required size are cut out in the edging.

- For the convenience of laying out skewers inside, special guides are made of metal strips or corners. They are cut along the length of the barrel, cuts are made on the corners with a step of 10 cm. The guides are welded inside.

With lid

If there is a desire to provide the brazier with reliable protection from wind or precipitation, it is supplemented with a cover. For this, two options are applicable:

- Attach the upper half of the cut barrel to the lower half, which will perform protective functions. For this, its edges are also polished, then edged with a metal corner. After that, both halves are fastened using steel door hinges.

- Instead of cutting the barrel strictly in half, you can mark a rectangle of sufficient size in the upper part and cut only it. Then sand the cuts, form the edging and attach the loops.

To top it off, the "newly made" brazier is equipped with a chimney. It can be discharged through a drain hole or through a larger round hole made. For manufacturing, steel pipes with a diameter of 7 cm welded with the letter "G" are used.

- This brazier is perfect for a large company.

Painting and decor

If the barrel is old, it is advisable to get rid of the dirt and rust accumulated on the surface. For this, firing is provided. The barrel is moistened on all sides with a rag soaked in diesel fuel, then set on fire and waiting for the fuel to burn out.

To make the structure more durable and beautiful, the entire surface is painted. For this, a spray gun and heat-resistant paint are used. You need to apply the paint in several layers, then give it a day to dry.

For convenience, it is advisable to equip the brazier itself and the lid with handles for opening and carrying, using ordinary door handles. Along the edges, it is advisable to build shelves for cutting meat and dishes.

With smokehouse and grill

If there is a need for barbecue, a removable stainless steel grate is additionally constructed. To install the grill, several steel wires of a centimeter diameter are mounted inside or fastened on both sides by two corners.

If the wire is threaded through, that is, brought out and a handle is attached to it, you can further use it as a spit.

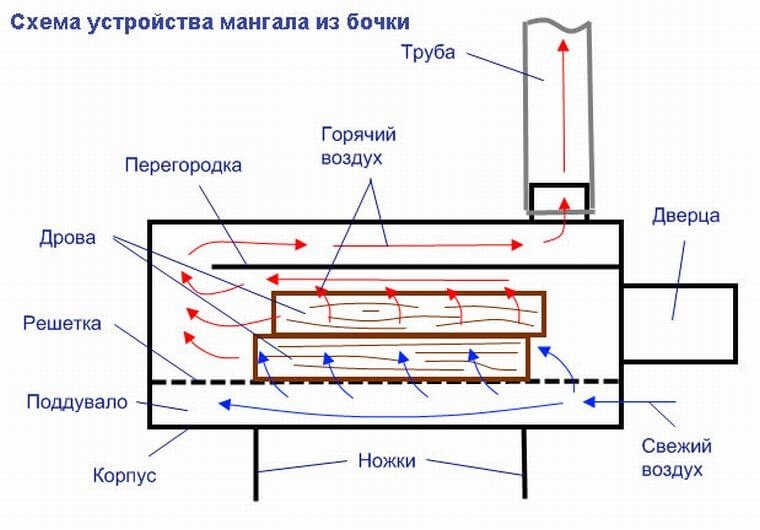

You can also upgrade the device to a smokehouse. To do this, a hole is made in the lid with a drill to exhaust the smoke. A more serious version of the smokehouse is mounted from two barrels. The second is installed from below, vertically. The upper part is removed in it, cutting out a wave-like recess into which the brazier is horizontally inserted, a door is made from below for storing fuel.

A skilled craftsman will make a barbecue grill in a day. It will take another day for the paint to dry, and that's all - you can invite friends or household members to barbecue!