How to build a staircase to the veranda: a step-by-step guide and photos of finished structures

Content

Types of stairs

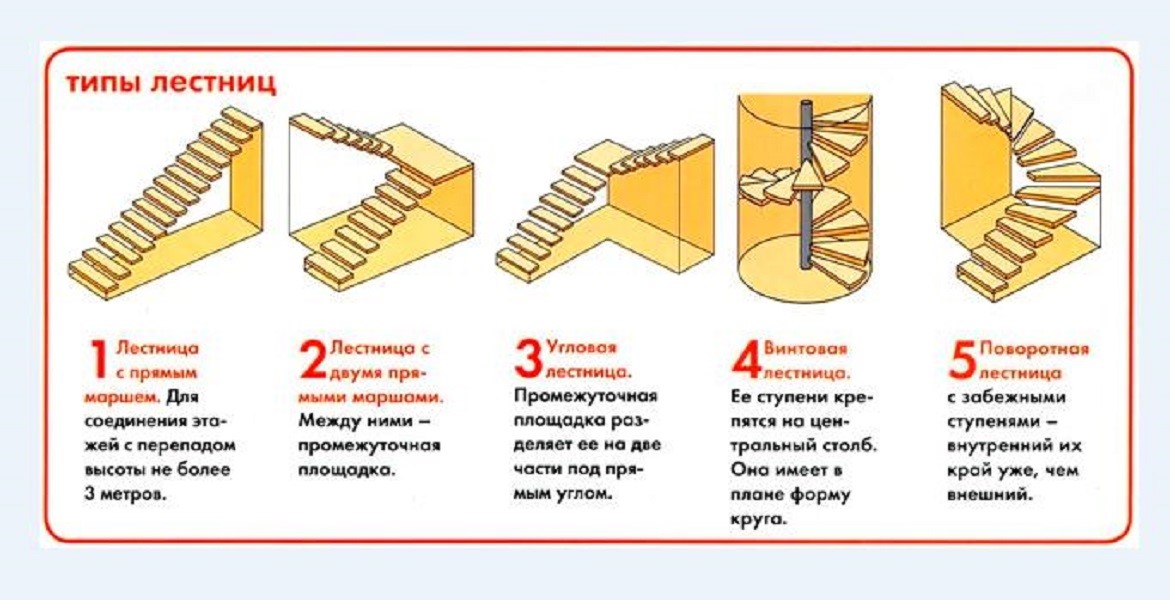

Before starting construction work, you need to decide on the type of stairs:

- Screw. A compact building that is best suited if you need to make an ascent from the street to the upper floor. However, it can be difficult to make a project, since calculating the turn angle and the number of steps requires special knowledge.

- Simple marching. It is quickly assembled, the technology for different materials is almost identical. Can be on one or two kosoura.

- Corner. This is done if the base is high. It can be with one or several turns. Reliability is ensured by fixing intermediate platforms to the walls of the house.

- Rounded. More complex in the development of the project, however, such inconveniences are compensated by the greater variability of forms and aesthetic appearance.

- Without kosour. The peculiarity of the building is that the steps are immediately embedded in the wall of the house. Not suitable for all buildings.

Video "How to make a ladder with your own hands"

The video presents the highlights of the construction.

What to build from

Today the building materials market offers a wide range of raw materials for construction: wood, brick, metal or concrete.

Wood is prized for its ease of handling and sawing. It is distinguished by its durability, and some types of wood, such as oak, elm or beech, serve even in conditions of persistent humidity. Also among the positive qualities: environmental friendliness, naturalness and aesthetic appeal, "high cost" of appearance. Nevertheless, it is important to point out the disadvantages of this raw material: the need for treatment against decay and rodents, careful care, especially if the humidity is increased, the high cost of high-quality raw materials.

A metal building will stand for more than a dozen years, it will look presentable and aesthetically pleasing, the owner will have a large number of design options. But metal structures require careful processing from corrosive processes. Among the disadvantages are the high cost of raw materials and work, especially if forged elements are provided. Work requires experience, especially with a welding machine and a bending machine. The reliability of the structure and its appearance depend on the quality of the welds.

A concrete structure will last a long time, weather conditions are not terrible for it. But the use of such raw materials is not widely popular due to the high price and excessive massiveness of the final building.

Making brick steps does not require colossal experience or specialized expensive tools. It differs in an average price, but you will have to think about additional cladding.

Construction of wooden steps

When building such a structure, you must provide for the type and amount of materials, methods of fastening and support, parameters, including the number of steps, as well as design.

When creating a project, designate the frame of the structure so that the base of the veranda and the base of the stairs make up a single monolithic block. If the staircase is built later, consider other features of the house as well.

You can order the project from professionals who will carry out accurate measurements. In addition, you can order a finished product if the price does not repulse you.

To make wooden steps yourself, you need a circular saw, jigsaw, screwdriver, screwdriver, building level, tape measure, ruler and protective gloves.

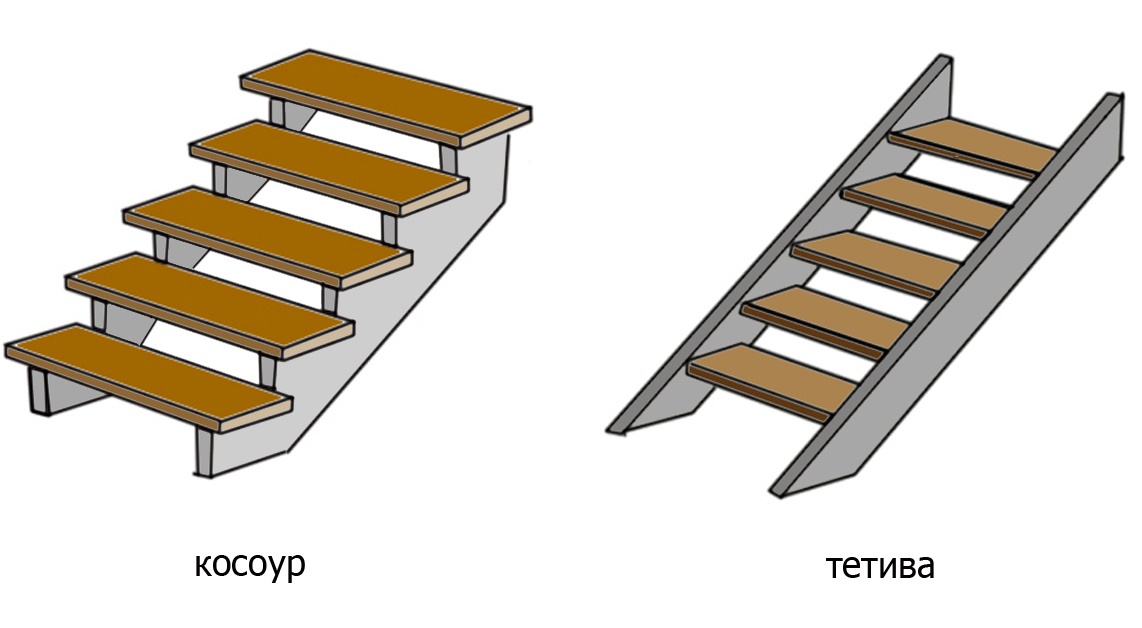

If you decide to carry out the work yourself, then you should know about two main methods of construction:

- with kosoura - overlaying steps on the support beams;

- with a bowstring - fastening steps into special grooves between the support beams.

The first method is considered more reliable for buildings on the street. For kosour and steps, you can take a board of 50-60 mm, the riser can be made of a board thinner.

To install a wooden staircase, you need to follow these steps:

- Creation of a detailed drawing.

- Site clearance and preparation.

- Pouring the concrete base at the place of support. To do this, fill the dug hole with a cushion of rubble and sand and fill it with cement so that the thickness of the base is at least 10 cm.

- Make stringers. For a construction with a width of 90 cm, at least 3 parts are needed. Use a right triangle for the markup to be correct.

- Mark the estimated distance between steps on the board and mark using a triangle. When doing this, take into account the thickness of the floor and base.

- Cut the grooves using a circular saw or jigsaw. If you are using a saw, it is recommended that you make the final cuts with a hand saw.

- Cut out the steps and risers. It is recommended that the step protrude a few centimeters above the riser.

- Start the installation by attaching the stringers. The final fixing is carried out only after checking the reliability of the parts and compliance with the project.

- Install steps and risers.

- Install balusters and decorative pieces.

Metal construction

As already mentioned, metal is susceptible to the harmful effects of rust, therefore it is recommended to install elements of this material under the roof.

Metal elements are made in the same way as wooden ones. For stringers, it is recommended to take I-beams or channels with a width of at least 15 cm. The steps to the stringers are fixed with fillets or corners.

In the first option, you need to make triangles in which one of the sides will be equal to the width of the tread. The second method consists in cutting the corner into equal lengths and welding to the inside of the stringer.

The floor of the terrace or veranda is recommended to be made of wood, concrete or expanded clay, since, unlike metal, they do not create unpleasant noise.

Brick

Although the brick is easy to install, it is notable for its low resistance to precipitation. Regular brick easily absorbs moisture and can begin to crumble in case of temperature changes. To prevent such a problem from overtaking homeowners, it would be rational to take a ceramic or silicate type of material. It is worth noting that the price will also rise in this case.

The first thing to do is a foundation deepened by 50–60 cm: dig a hole, fill in a sand cushion and fill it with mortar. Then lay out the side and lower parts, you get a kind of "box" in which you need to fill and tamp the rubble. Now you can start laying the second step so that it partially covers the previous one. Then again it is necessary to fall asleep with rubble. The seam on the front masonry must be done carefully, especially if additional cladding is not expected, and wiped with protective water-repellent agents.

The surfaces themselves can be clad with clinker, tiles or artificial stones.

Try to choose finishing tiles with a rough surface, made by vibration pressing. If the tile is vibrocast, then it will have only a smooth surface and will be covered with ice during frost, which is traumatic.

To solve the problem of moisture, you can make treads from wood with special treatment, make the entire structure out of bricks and cover the structure with facing tiles or fill the box with expanded clay.

So, the process of installing a staircase on a veranda with your own hands can be simple and budgetary. Choose a quality material, choose the type of structure you need, follow the instructions during construction, and you will get the desired result.