We make a garden chair out of wood with our own hands: a unique product from scrap materials

Content

Types of wooden chairs

With proper care, it will last 12-15 years. You can offer a double model - the best option for summer gazebos and terraces attached to the house. Based on personal preferences and operating characteristics, you can also do:

- Kentucky or bar shell chair. It is better to use walnut or oak in the work. These materials withstand mechanical stress well, and their original texture allows you to save on wood finishing products.

- Lightweight folding models are suitable for travel lovers. It is acceptable to use them in open-type gazebos, entwined with flowers. Such furniture does not require a lot of space, which is especially important for owners of small-sized extensions.

- Upholstered armchairs on wheels are a great option for people prone to depression. Providing a pleasant tactile sensation, these products have a calming effect.

- Sliding options for daily relaxation and outdoor sleeping.

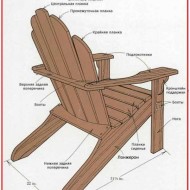

- The Adirondack is throne-shaped with a slightly convex seat. In such an armchair it is convenient to read, do handicrafts and meditate.

Before you make chairs out of wood with your own hands, you need to think over the shape of the back, legs and armrests. In this case, the height of the seat should not be lower than 96 cm. This is important for the formation of correct posture. If you need furniture for your dining area, folding solid wood is the best thing to offer to amateur carpenters.

Dust is almost invisible on these chairs, and they are also easy to clean and are well suited for people of different weights. It is acceptable to use multi-shaped pallet chairs not only on terraces, but also when decorating the main premises. The maximum budget of such a project often does not exceed 1.5 thousand rubles.

Video "Wooden chair for the garden with your own hands"

In this video, you will learn how to make a quality wooden garden chair with your own hands.

Preparation for work

When choosing a specific model, it is important to take into account the maximum load on the supporting elements of the products. For example, with a weight of 95 kg, the owner can try to combine wood and forging in work. This will increase the durability of outdoor furniture suitable for passive relaxation, eating and sleeping. In the absence of a foundation, it is better to use pendulum products that swing equally well on the ground, sand and grass.

Wicker chairs are distinguished by their exquisite appearance, but they do not tolerate heat and moisture poorly. Therefore, they are often made for closed-type outbuildings. The maximum comfort is provided by hanging furniture in the form of a basket or a hemisphere. Here, in addition to wood, a hoop from a pipe, rings, carabiners, dense fabric and several zippers will come in handy for a novice craftsman.

In order to avoid technical errors, it does not hurt to familiarize yourself with the various drawings of wooden chairs before work. We are talking about detailed graphic images, where the features of the connection and fastening of most parts can be indicated.

Material selection

Hardwoods are the best raw material for garden furniture. Oak, for example, is highly durable and hard. It lends itself well to dry processing and hardly absorbs moisture. For the implementation of original design ideas, beech is more suitable. This wood is famous for its homogeneous texture, and the variety of natural shades creates unlimited possibilities in the choice of style solutions. The only drawback of the material is its high hygroscopicity. For this reason, it needs pre-treatment with protective compounds.

You can also use rowan, ash, elm and sycamore in the work. Softwoods such as pine, cherry, cedar and maple are more suitable for decorating finished products.

Model selection

Folding chairs are often called transformers. With one movement of the hand, they turn into sleeping places designed for adults and children. This is the best option for the street and small premises. If the area of the terrace exceeds 15 squares, and the furniture has to be rearranged from time to time, it is better to take a closer look at the functional models on wheels.

The easiest way is to knock a chair out of pallets. For the single version, you will need 2 pallets of standard sizes. In this case, the distance between the top boards should not be less than 45 mm. The main thing is to properly fasten the seat and backrest, sand the wood and make a tilt. From tools you will need hammers, bolts, primer and nails. As for the main raw materials, you can order it on the Internet at a price of 120 to 190 rubles per pallet or browse through the ads in the "I'll give it for free" heading.

Tools

An inexperienced carpenter will definitely need a circular saw. With its help, wood can be cut at a convenient angle in the longitudinal or transverse direction. Units with protective covers and with a built-in engine braking function are especially popular. Other tools include clamps, drills, a drill, and a hand saw.

When choosing a joinery, it is more logical to give preference to a device with a small amount of backlash. This way you will be able to provide convenient cutting of the main and decorative elements with millimeter precision.

Life hacks of masters

The consistent processing of raw materials contributes to the long-term use of the furniture. At the first stage, the wood is sanded. Then it is impregnated with protective compounds that increase its resistance to ultraviolet light, moisture and insects. The next step is priming and painting the chairs. Irregularities on the surface of the materials should be filled with a flexible trowel. If there are minor scratches, use a regular putty.

In the conditions of using chipboards, you will need:

- decorative edge, which is usually attached to the ends of wooden chairs and armchairs (its main purpose is to hide the unaesthetic appearance of the product inside);

- a circular saw that guarantees a neat cutting of the material;

- masking tape is glued to the cut line to avoid coloring the chipboard;

- the rasp removes irregularities well; for better processing of sheets with a film coating, you will need a plane;

- dyeing of finished products in three layers to neutralize formalin.

Step-by-step instruction

If you have a drawing of an Adirondack chair at hand, you will get an original product with amusingly curved legs. It is important that they are slightly higher than the seat. To do this, the ends of the materials must be shortened by 1.5–2 cm. Step-by-step instructions for any model of the chair will help fix 8 to 10 seat slats, backs of products, front and rear legs without errors. It will be useful to make drawings of the lower supports and armrests.

Wooden shell chair

A jigsaw is required for processing solid wood or 16 mm plywood. The main thing is to adhere to smooth movements in order to avoid slight irregularities and significant deformation of parts.Curved plywood can be used only if you have already dealt with such manipulations before. At the first stage, it is important:

- Make a drawing of the future product indicating the dimensions and location of all elements.

- Cut out the blanks.

- Treat the parts with several layers of varnish: the first time along the grain, and the second time across, so that the surface is perfectly flat.

- Fix the elements with wood glue, and connect the individual parts with clamps according to the instructions. Decorative screws can also be useful in work.

Pallet armchair

A few standard sized pallets, a Phillips screwdriver, sandpaper, fasteners, and paint come in handy for creativity. First, the pallets must be sanded with abrasive materials. If time is running out, it is better to use a special grinding technique. Then we form the seat. To do this, we define the center point of the first pallet and then cut it along the material. As a result, you get two products of different lengths.

A seat can be made of most of it with four support bars. In the same way, we make the back of the chair at an angle, but from the second pallet. The rest of the material will be needed to assemble the base and armrests. If you need to increase the stability of the supporting elements, attach additional bars to them. Remember to saturate the wood with antiseptics before using the chair outdoors.

Upholstered armchair

As a basis, you can take plywood with a thickness of 20 mm, and for upholstery - waterproof fabrics (heat-resistant oxford or an impermeable membrane). All parts are cut out according to pre-compiled templates, where their optimal dimensions and angle of inclination are clearly indicated. Next, it is important to process the ends of the product and form bends. After the sidewalls have absorbed the stain, you can start tightening the frame. To begin with, the back of the chair is upholstered, and then the seat. To this end, carpenters recommend upholstery nails with bulky heads.

To hide the strips, behind the frame part, artificial leather or foam rubber is fixed along the edge. And if you need to increase the shelf life of garden furniture, the attachment points are additionally treated with carpentry glue.

Chair for giving

Getting started assembling a two-seater "throne", you need:

- prepare 2 sidewalls, 40 transverse slats and 3-4 drawers;

- chamfer the side members and cut out the side members with a width of 110 mm;

- form the frame of the future product;

- attach the bars to the seat;

- putty the cracks, eliminate irregularities and varnish the finished chair.

In the work, you can use only well-dried materials, pre-treated with antifungal compounds.

High back armchair

If for a regular product you need 5–6 boards with a slab width of 5 to 7 cm, here the back will consist of about 8 more voluminous elements. The optimal distance between them is 1 cm. For a slightly rounded design, the gaps at the bottom of the product will have to be narrowed. Wooden parts are fastened using the groove method, and the joints are fastened with wood glue and self-tapping screws. To securely fix the supporting elements, you will need several vertical boards. For upholstery - chenille, pleasant to the touch, or better, a wear-resistant split.

If there is a detailed diagram of the product indicating the location of the cross bars, armrests, legs and backrest, the probability of technical errors does not exceed 3%.