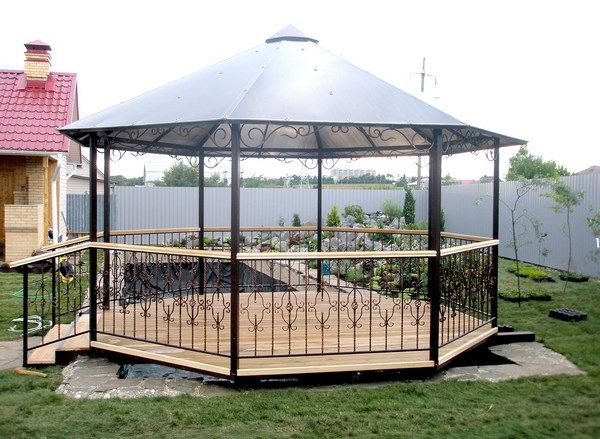

Rest for the whole family in the garden: do-it-yourself wrought iron gazebo

Content

Types and benefits

With a limited budget, it is more profitable to build a pergola decorated with bindweed. Belvederes look great on a hill. The unfenced area is an ideal place for an arbor. This type of wrought-iron gazebo impresses with its non-standard shapes and original roof structure.

Depending on the features of the structures, such structures can be:

- flower girls, where profile pipes are used as a support for creeping ficus and heders;

- pavilions with a dome-shaped roof;

- huts, woven from a multitude of twigs and wires;

- awnings attached to the main building;

- rotundas surrounded by fountains or artificial reservoirs.

Arbors can be round, square and multifaceted in shape. If we talk exclusively about their advantages over other options for summer cottages, the first thing to note is the resistance to heat and frost. Unlike wood, metal is not flammable, so it is possible to install a barbecue grill anywhere in the structure.

Video "DIY hexagonal metal gazebo"

From this video you will learn how to make a reliable metal gazebo yourself.

What is needed for construction

In their work, experts recommend using soft grades of steel. These materials contain the optimal amount of carbon, which greatly facilitates the process of artistic forging. Up to 70% of forged arbors are erected from shaped pipes. Such products withstand high humidity well and are ideal for the installation of load-bearing structures.

Stiffening ribs minimize damage from heavy loads, and comfortable pipe shapes facilitate independent work. For the manufacture of small parts, you need a cold-rolled sheet. It is easy to twist and roll, and thanks to cold deformations, it retains its original strength in any welding work.

Materials (edit)

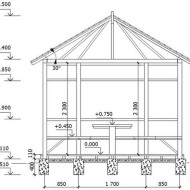

For the installation of the racks, you will need profile pipes with a wall thickness of at least 2 mm. If the owners plan to make a roof from light materials, for example, from soft tiles or reeds, it is better to purchase products of 50x50 mm. Pipes with a large cross-section of the profile are needed for the safe operation of slate in the future. When choosing building materials, it is equally important to take into account the weight of products for frame cladding.

As for cement, it is more profitable to use goods of the M-500 brand that are resistant to moisture and frost.

To arrange the floor you will need:

- dried wooden boards;

- varnished hemp;

- diagonal decking with wear-resistant plastic in the composition;

- porcelain stoneware capable of withstanding any load - this material does not ignite even at a temperature of 800 ° C, so the safe use of barbecues and bio fireplaces in such structures is not even discussed;

- wild stone or concrete.

Tools and equipment

For high-quality processing of metal structures, you will need an angle grinder. With its help, it is possible to cut any material of increased strength.Following the recommendations of experts, most buyers choose tools with protective covers that do not release sparks. In this case, the power consumption of the device should not be less than 700 W.

If you can't afford such devices, use a chisel. Pliers are needed to securely hold hot workpieces, and punches are used to punch holes. Hot working of parts is impossible without a blacksmith's hammer. And if there is an opportunity to rent a thread rolling machine, you can actually build a forged gazebo with your own hands from scratch.

Step-by-step instruction

The first step is to take care of a safe roofing arrangement. For this purpose, the supports are first welded, and then the arches. In order to avoid technical errors, it is better to work on a flat surface using a square.

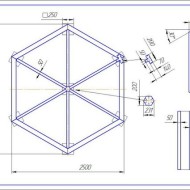

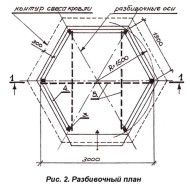

When marking a site, it is important to correctly calculate the distance between all corners. It is best to mark in the center of the shortest wall. The width of the entrance usually depends on the purpose of the building and the total number of residents. So, it is one thing to use a gazebo as a study, and quite another to arrange friendly gatherings there every day for a company of 8-10 people.

At the next stage, you need to dig a hole, install the support pillars, weld the piping to them, and at the very end, raise the already assembled roof.

Site preparation

The area for the gazebo should be freed from construction debris and tree roots. Then the site needs to be concreted, or better - revetted with ceramic granite. The optimal area for a wrought-iron gazebo is 3x3 m - 10-12 squares. In this case, it will be possible to decorate the structure not only inside, but also outside by means of original crafts made of foam and concrete.

Excavation of soil is carried out taking into account the marking. To arrange the drainage layer, you will need at least 6-7 cm of compacted sand and about a 10-cm layer of crushed stone.

The foundation

Here it is appropriate to talk about profile or ordinary pipes, decorated with original curls made of steel. First, they are introduced into the ground, concreted, and then the remaining structural elements are installed. In this case, the foundation can be omitted, and it is more profitable to replace the expensive natural wood flooring with paving slabs.

If the frame is made separately, it is better to prepare the lower strapping in advance. In the conditions of a strip and columnar foundation, pipes are supposed to be laid on the supporting structure of the structure. Such a gazebo cannot be disassembled independently, and to move it to another point on the site, you will need a construction crane.

Walls

For better protection from rain and wind, solid walls will be needed. If it is important for the owners to observe the beauty of the local surroundings from everywhere, it is more logical to install light trellised surfaces. In the future, they will become a support for plants.

It is important for the details to be given the optimal shape. This can be done in a home workshop, which does not need to be equipped with a furnace. It is enough to buy a special forging machine. It is better to use plastic and high-strength products in work. Unlike cheap "semi-finished" products, they lend themselves better to cutting, grinding and trimming. In this case, the metal is not deformed.

Finished forged elements, in particular decorative rosettes, cores, inserts and friezes, are sold in specialized stores.

Roof

When using bituminous shingles, it is better to build the frame from lining and beams. In the ends of the racks, 20-centimeter pieces of wood should be hammered. In this case, it is important to correctly install four rafters of 2.5 m each. They can be attached to each other with nails, and for greater strength it is better to use stainless steel corners.

It is important that the rafter legs protrude at least 3 cm beyond the perimeter of the harness. For this, a bar 80 cm long is attached to the auxiliary board installed in the center.After the work is completed, the crate can be installed.

Floor finishing

In spacious gazebos with barbecues, concrete floors are most often made. To do this, inside the tape base, you need to remove a 20-centimeter layer of soil, then tamp the sand cushion and attach a damper tape from the side of the supporting structure. This way you can avoid cracks in the event of uneven shrinkage.

The optimum screed layer is 5 cm. The mortar is poured to the level of the foundation. If you need to minimize the cost of supplying cement, it is better to increase the thickness of the crushed stone layer from below by 2.5 cm. Professional installation of paving slabs involves the use of special frames for the correct laying of the material. Here, the leveling layer of sand should not be less than 4 cm, and it is better to mix the cement-sand mortar in a ratio of 1: 3.

Territory

You can plant colorful anemones around the wrought-iron gazebo. These perennials are impressive with large buds and velvety leaves. In combination with astilba and badans, they are able to decorate any area. Asters feel better in partial shade. Summer gazebos can also be decorated with gazania. This flower blooms in early June and quickly takes root in clay pots.

From artificial decorations, crafts made of plastic and artistic concrete are suitable.

Gazebo with barbecue

For safety reasons, it is better to install such a building away from the garage, sheds and compost pits. To avoid technical errors, a drawing should be drawn up in advance indicating the dimensions and location of each structural element. At the next stage, the marking of the site is done, after which you can lay the foundation and pick up a high-quality barbecue with a base thickness of at least 40 cm.

The product must be equipped with a flue gas outlet and a pipe. This is necessary for the drainage of precipitation.

Access to the barbecue from both sides will allow you to avoid accidents at the time of an unforeseen fire. And this arrangement of the barbecue will allow you to cook 2-3 dishes at the same time on one brazier.