How to insulate a veranda: an overview of the best materials and the rules for their use

Content

Internal and external works

When insulating any buildings, two methods are used:

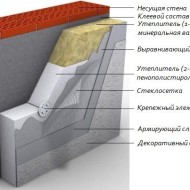

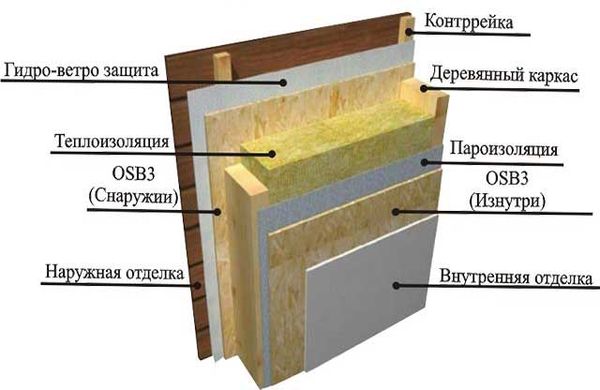

- External insulation using modern polyurethane foam and mineral materials allows the dew point to remain outside the main structure of the house. In this case, the risk of the appearance of fungi, mold on the walls of the building is reduced. The advantage of this method is the complete protection of the building from moisture. It is the external insulation work that is used in the construction of residential buildings and is considered more correct.

- Internal insulation has a high probability of the formation of damp places, since the dew point "enters" the house and moves from the insulation to the wall, depending on the external and internal temperatures. Various layers are used to prevent the formation of mold. Unlike the outdoor method, this insulation allows you to preserve the exterior of the building, which is especially important when insulating a veranda.

Video "Insulation of a private house"

From this video you will learn how to properly insulate a private house with your own hands.

Steam and waterproofing

The location of the dew point inside any wall is an indicator of the possible appearance of moisture on the inside or outside surface. To regulate its movement, waterproofing materials are used. Vapor barrier films allow moisture to move in one direction and not in the other. Waterproofing prevents moisture from moving in any direction.

For example, external insulation is covered with a vapor barrier, due to which the insulation is not exposed to precipitation. If the moisture in the insulation rises when the temperature changes, then due to the correct location of the film, the effect of moisture removal is achieved. When insulating from the inside, the vapor barrier is alternated with air gaps or a hydro-barrier is used.

Materials for thermal insulation

Modern technologies allow the use of insulation materials, which, with a small thickness, retain heat much better than the material of the building itself. The use of these materials allows you to insulate a wooden terrace with your own hands. Performing such work will make the veranda suitable for winter living. Expanded polystyrene and mineral insulation differ from each other in durability and toxicity.

Styrofoam

This material is a foamed cellular mass of polymers, usually white in color. Due to the large number of synthetic components, it is highly toxic. On contact with fire, it emits corrosive smoke hazardous to human health.

Foam is made in the form of 1x1 m or 0.5x1 m slabs. The material can have different densities, which affects the heat resistance and strength of the material. Plates are produced in various thicknesses. This contributes to the widespread use of foam. It is convenient for cutting and making various, even very complex shapes. This insulation does not absorb moisture and retains its properties and shape for any period of use.

Minvata

This material has long been used as insulation.He fully copes with the tasks. Mineral wool consists of glass fibers, therefore it is often called glass wool. Mineral wool is resistant to temperature extremes, sound insulation, thermal insulation.

Glass wool slabs can have different fiber orientation: horizontal, vertical or spatial. This allows it to be used in various building structures. In the manufacture of this insulation, resins are used, but their number is so small that glass wool is considered environmentally friendly.

When exposed to fire, the mineral wool is destroyed. To eliminate this drawback, its analogue was created - stone wool. Manufacturers claim that these materials are moisture resistant. But the experience of using mineral wool has shown that over time, the structure of the bonds of the fibers is broken, and the material loses its properties.

Expanded polystyrene

A newer type of foam has been produced using polymeric styrene additives. Foamed granules of such insulation of a smaller fraction, therefore, the finished polystyrene boards have a higher density, and as a result, thermal insulation.

The insulation contains a large number of chemical elements that are very toxic. When foaming such a material, natural gas is used, therefore, the insulation is classified as flammable. Special fire-resistant polystyrene foam plates are produced, in the manufacture of which carbon dioxide is used instead of natural. Such insulation is positioned as fireproof.

This insulation does not absorb moisture, retains all its properties throughout the entire service life. Polystyrene plates are made of various sizes and thicknesses, which allows them to be widely used in the insulation of any structures.

The procedure for work on internal insulation

After choosing the insulation material, we will prepare the surface of the cottage veranda for the start of work. All interior trim and trim will need to be removed. Taking into account the internal design, we can ignore the weather conditions. At the same time, it is better to place the insulation itself in a dry, even cold room or under a canopy. The use of wet boards will be an undesirable factor when installing them.

For the reliability of internal insulation, slabs of any material must be installed in a pre-prepared frame. We make the frame from wooden slats, which must be prepared in advance. When assembling the frame and installing the insulation, we will use the following tool:

- hacksaw;

- screwdriver;

- stapler;

- measuring devices.

Walls

Any heat-insulating material can be simply glued to the surface of the insulated structure. But it will be more reliable to use a frame for their installation. Having freed the surface of the walls from the interior decoration, we proceed to the installation of the slats. We make the thickness of the wooden frame the same as the thickness of the insulation.

Using a measuring tool, we check the correct installation of the vertical rails. We make the width of the slats in accordance with the size of the insulation boards. Under the window openings, we restrict ourselves only to vertical slats. When insulating a closed wall, we make several transverse jumpers.

We insert the insulation into the fabricated frame and glue it with a vapor barrier film. For ease of installation, we first fix the vapor barrier with a stapler in some places, and then in others.

It is important to install the film correctly. It should release moisture from the insulation and not allow it to penetrate into the slabs from the room.

Ceiling

On the inside of the roof truss system, we mount the slats for the insulation plates. The direction of the slats is not important. It is important to make sure that the plane of the ceiling insulation touches the wall plates. At the same time, cold corners or planes without insulation were not formed.

We install the slabs into the prepared frame, then we attach the vapor barrier film to the ceiling in the same way as to the walls. On top of the film, we will make a crate of arbitrary thickness, perpendicular to the frame slats. This lathing will support the insulation boards and serve as a load-bearing function for the future finishing of the ceiling.

Floor

After the dismantling of the flooring has been completed, it is important to think over the literacy of installing insulation boards on the floor and lathing. After completing all the insulation work, the veranda should become a warm living room. To do this, make sure that there are no places between the wall and floor insulation plane that can freeze through. The lower part of the wall insulation should be docked with the floor.

Before the installation of the insulation frame, we carry out a crate with an arbitrary section of the bar, which will support the insulation plates. We will mount this lathing flush with the logs of the old floor sheathing. We make a frame for insulation and install plates in it. We cover the insulation with a vapor barrier film and fix it. The frame slats can be used for floorboarding. The direction and width of the frame laths should be considered in advance.

After warming all surfaces, we sew up the inner space of the veranda with finishing materials. We glaze the open space. We use double-glazed windows taking into account their use in the winter. If the building already has windows, then we will insulate the glass using a special heat-resistant film, which we will stick on the inside of the building.

Having familiarized yourself with the various types of insulation and the features of their installation, you can safely use the acquired skills to carry out the insulation of any buildings.