Sidewalk tile paths in the country - a solution for economical summer residents

Content

General rules

There is a large selection of paving slabs on the construction market, which differ in shape, parameters and color. The advantages of the material include:

- durability;

- the ability to withstand large dynamic loads;

- no difficulties with installation;

- ease of use of finished structures;

- a variety of shapes, sizes, textures and colors.

When choosing a building material, it is recommended to pay attention to the surface texture, size, shape and color of the stone. It is equally important to familiarize yourself with the features of the stone-making process. A stone with a thickness of 2.5 to 4 cm is suitable for arranging garden paths. If the path will be used by vehicles, it is better to choose denser paving stones. For this reason, the degree of dynamic load of paving slabs is one of the most important criteria for choosing a building material. Side plates must be equipped with drainage systems.

As for the type of laying paving slabs, the classic version of the location of the stone is very popular with summer residents. The drawing "chess", "offset", "herringbone" or "geometry" looks no less interesting.

Video "Technology of arrangement of a garden path"

In this video, experts share secrets and recommendations on how to lay out a street path from paving slabs.

Laying technology

The garden path is an important element of the suburban area, since it connects all significant functional objects. For the arrangement of paths, you can use wooden planks, wood boards, gravel and paving stones. The latter option is considered the most practical, strong and durable. Paving paths are resistant to temperature extremes and various precipitation. Subject to the installation technique and proper care, such a path in the country will last for more than a dozen years.

So, let's figure out how to make do-it-yourself paved street paths:

First, you need to develop a schematic drawing and come up with a sketch of the future pattern. The drawing can be done manually or use specialized computer programs for drawing. The next stage involves the selection of materials and the preparation of construction tools. When choosing paving stones, one should take into account the texture, size and color of the stone, as well as the degree of dynamic load.

In the process of laying paving stones, you will need the following devices and tools:

- control and measuring and marking devices;

- shovels - bayonet and shovel;

- a special device for compacting the soil;

- a perforator with a mixer attachment or a small-sized concrete mixer;

- machine-grinder with discs for working with concrete and stone;

- trowel, small sledgehammer, mallet hammer with a rubber base;

- garden cart, broom, hard bristle brush, watering hose;

- protective gloves and work clothes.

Preparation of the base

A properly prepared base is a guarantee of the longevity of your garden path. First of all, you need to break down the site into sectors.Then the marking of the future path is made, the width, length and bends of which must correspond to the measurements specified in the scheme.

The beginning of the path is marked with a wooden peg. Subsequent pegs are driven in at a distance of 1.5–2.5 m from each other; at turns and bends, the guides are set much closer.

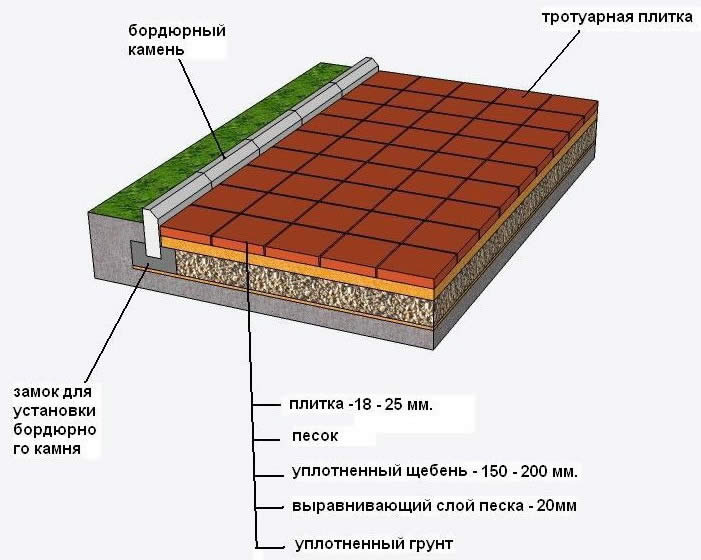

After finishing the marking, you can start forming the base. With the help of a bayonet shovel, recesses are made along the marking line and the top layer of the earth is removed. The depth of the trench in the center should be in the range of 20-30 cm, on the sides - 35-45 cm. The side recesses are intended for installing curbs.

The tamping device is used to level the working platform and check the evenness of the horizontal plane. Then a three-layer base cushion is formed from crushed stone, sand and dry cement mortar. It should be noted that each layer must be carefully leveled and tamped. Between the layers, you can make an interlayer of geotextile fabric, which prevents soil subsidence and acts as a drainage system.

Installing the curb

The border prevents the gradual spreading of the base of the garden path. Sometimes, instead of a curb, storm drains or formwork from a corner are used.

The installation of the curb is carried out on a base cushion formed of sand, geotextile material, crushed stone and concrete mortar. Such a "lock" reliably fixes the curb and prevents the sidewalk tiles from moving.

Laying of paving slabs is possible after 20-24 hours. If the weather is damp and cloudy, which prevents the concrete from hardening, it is better to wait another 1-2 days.

Laying tiles

Laying paths from paving slabs starts from yourself. Otherwise, there is a high probability of surface subsidence during the formation of each subsequent row. The paving is paving row by row, with each line being checked with a building level. Sagging and tilted stones are lifted with a trowel and leveled by adding a dry cement-sand mixture.

If the drawing involves cutting paving stones, it is recommended to first lay the solid elements. Then, with the help of a grinder and discs for working with concrete, side and corner stones are cut.

According to the recommendations of experienced builders, the side elements are laid at a slight slope towards the curb. Consequently, when it rains, water will not collect in the center of the track.

Sealing of seams

At the last stage of laying a garden path from paving slabs, the surface is leveled and the joints are filled. Using a building level, you need to check each row horizontally and vertically. Even a slight deviation from the norm requires dismantling and troubleshooting. Since in the future, it is in this place, when the paving stones begin to sag, a pit will appear.

When the path is completely ready, you can start sealing the seams. Cement and sand are mixed in a 1: 4 ratio. A dry cement-sand mixture is applied in an even layer to the surface of the track. Using a brush with stiff bristles, the inter-row seams are filled. The remains of the dry mixture are swept away with a broom, the surface of the path is poured with water from a hose. When the surface is completely dry, the procedure for filling the joints with a dry cement-sand mortar should be repeated.

The design and drawing of the garden path depend on the preferences and skill of the summer resident. To make the personal plot look harmonious, it is recommended to design all functional areas in the same style. Often, the colors and shapes of the tiles are chosen in accordance with the decor of the country house, garden gazebo and other architectural buildings on the territory of the summer cottage.