Hipped roof for a gazebo: roof options and assembly techniques

Content

Features and types of construction

The main design feature is the absence of pediments, due to which it is not necessary to take into account the wind rose in the work. The combination of trapezoidal and triangular slopes contributes to better drainage. With the right materials, the roof can withstand a 4m layer of snow. And if the hips are slightly reduced, the attic space will become a cozy place for families with children.

Optimum stiffness values are achieved through corner ribs. Therefore, even if the gusts of wind reach the most critical levels (from 75 to 90 m / s), the hip structure does not deform. Volumetric overhangs protect the outer surfaces of buildings from rain. And since the hipped roof retains its attractive appearance for many years, this is a win-win option for connoisseurs of the most original architectural forms.

Depending on the location of the support boards and the valley, a complex structure can be:

- Classic with straight rafters. Stiffeners and overhangs are at the same level here.

- A hipped roof that looks like a pyramid or polygon with the same sides. The pediments are also absent here, and the eaves overhang runs along the entire perimeter of the gazebo. If there is a load-bearing wall, it is better to install the rafters in a layered way. This will help avoid too much pressure on the walls.

- Chinese with upward curved corners. In this case, the roof is supported by a central pillar, so tremors are not able to disrupt the integrity of the structure. If you rely on the data of detailed drawings, such a roof can be built by hand in about 5 days.

- Danish with a trapezoidal pediment.

- Hip with a lot of stingrays. This is the best solution for the construction of octahedral buildings.

Video "How to build a summer gazebo"

From this video you will learn how to build a summer gazebo with your own hands.

Roofing material options

As in the case of flat roofing, the choice of materials depends on the composition of the products and their performance. For example, euro slate demonstrates good resistance to mechanical stress. It can withstand up to 280 kg of snow per 1 sq. m of surface. In work, it is better to use multi-colored sheets 200 cm long. The optimal width of products is from 95 cm and above.

Dark shades of slate reflect up to 45% of direct rays, while light materials, on the contrary, attract heat. If the building is located on the north side, where the sun looks no more than 3 hours a day, it is acceptable to use translucent sheets.

Soft tiles absorb noise better than ceramic tiles. This material is characterized by increased resistance to sudden temperature changes, moisture and ultraviolet radiation. If we talk exclusively about installation, the list of advantages should be supplemented by fast installation of complex roofs, ease of transportation and minimal waste.

Form stability of products is possible due to cellulose. Maintainability is provided by modified bitumen.Unlike ceramic tiles, the flexible coating is more impact-resistant, which is especially important for the most rainy regions of the country. Among them: Severo-Kurilsk, Moscow and Petropavlovsk-Kamchatsky. Shingles covered with several layers of protective dressing show great vitality in any climate.

Supporters of transparent structures are advised to make a polycarbonate roof. In winter, the material retains heat well and allows up to 95% of natural light to pass through. Lightweight honeycombs can be processed with power tools and improvised tools, and the optimal sheet thickness (from 35 to 40 mm) guarantees one hundred percent protection from bad weather.

How to assemble with your own hands

First of all, it is necessary to choose the optimal angle of inclination of the roof. To this end, it is important to take into account not only the total amount of precipitation per year, but also the windiness of the regions. For example, in Pevek, Chukotka, the wind speed often reaches 45 m / s, so the angle of inclination should not be less than 55 °. In less windy St. Petersburg and Gelendzhik, this figure can be reduced to 35 °.

It is better to consider further steps for the construction of a hipped roof in detail:

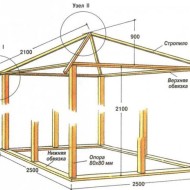

- First, you need to make a drawing of the future structure indicating the location and dimensions of the rafters, tightening, pillar, wind beam and Mauerlat.

- Construct a foundation to evenly distribute the load on the outer surfaces of the building.

- Install the hydro-barrier and secure the Mauerlat.

- Place the supporting elements on the load-bearing partitions.

- Make a crate.

- Fasten the frame with self-tapping screws.

- Cover the roof with ondulin or polycarbonate.

Be sure to prepare the hanging rafters when starting your hipped roof. Their ends can be cut at right angles, vertically or horizontally. At the end of the work, fill in the wind boards and prepare the sheathing for the roofing material. The optimal distance between the posts is 90–120 cm. For high rates, you will have to install jibs.

Useful in the work of drills, hammers, galvanized nails, screws and saws with sharp teeth. If the assembly of the most important elements is carried out at a height, it is important to stock up on ladders and safety ropes in time. Only pre-processed materials are suitable for installation.

For example, low-grade wood species is not the best option for capital construction. But if there are no other ideas, you will have to cut out the core or the layers adjacent to it. Logs processed from all sides are a source of quality beams.

So that the material does not collapse ahead of time, it should be treated with special glue or lime. To increase the fire resistance, a flame retardant treatment will be required. An electronic calculator will help determine the exact amount of materials.

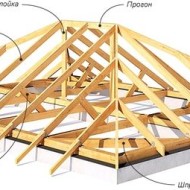

Rafters

It is better to form rafter forms on the ground. Then they can be lifted to a height using a construction crane. If this is not possible, try assembling the structure directly on the roof. Elements resting on the inner corners of the building are called diagonal. They are about 30 cm longer than standard beams. And since it is the layered rafters that bear the main load, in order to avoid destructive processes they will have to be strengthened by connecting several boards.

Horizontal racks and slopes contribute to the same goal. The optimal length of the rafters is 7 m.Beginning with the independent installation of the system, it is important to remember:

- paired boards can withstand higher loads than solid logs of the same diameter;

- beams and rafters are supposed to be knocked down from identical materials;

- with the length of the beams from 8 to 9.5 m, additional racks are not needed, another thing is 5-meter products that require the installation of a truss;

- when using 12-meter boards, intermediate supports will be needed;

- staples, galvanized nails and clamps are ideal for fastening elements of different shapes.

The device of the rafter system of a four-pitched roof at full employment takes from several days to several weeks.

Coating

It is better to choose keramoplast from polymer materials. This group of coatings includes euro-slate and metal tiles. Light weight of products - about 5 kg per 1 sq. m of surface - contributes to the quick installation of impact-resistant sheets. They are dyed in all colors of the rainbow at the production stage, thereby increasing their resistance to fading.

Ondulin withstands wind loads and temperature changes well. Since the material does not deteriorate from acid rain, it is convenient for them to cover roofs in industrial regions. The minimum shelf life of such structures often exceeds 25 years.

Recently, consumers have begun to show more interest in standing seam roofing. The main advantage of this coating is the tightness of the joints, due to which the roofing cake does not deteriorate under the influence of atmospheric phenomena. Lightweight sheets with a thickness of no more than 0.5 mm reduce the load on the rafters, and their perfectly smooth surface ensures high-quality drainage.

In gazebos with barbecues, it is better to cover the hipped roof with composite tiles. The basis of the material is steel sheets that are resistant not only to thermal, but also to chemical influences from the outside. This is the best option for constructing a broken and multi-sided roof.