How to sheathe a gazebo: advice from craftsmen on external and internal work

Content

Finishing features

More than 40% of the heat escapes through the windows, and the same amount is absorbed by poorly insulated ceilings, roofs and walls. It is unrealistic to spend the winter in such a structure, so we advise you to sheathe the gazebo with a block house or polycarbonate before the cold weather. Shock-resistant materials withstand temperature changes well, do not warp, maintain an optimal level of humidity in rooms.

This is important not only for people, but also for the active development of indoor plants, a third of which wither when the air is dry over 22%. The hard surfaces of the building can be finished wet or dry. In the first case, it will be necessary to level the walls with plaster, and in the second, dust-free sheathing with sheet materials. In a small-sized room, it is better to attach them to the walls, and not to the frame. Otherwise, the already small area of the gazebo will "lose weight" by 2-3 cm.

Construction scissors, glue, a spatula, a special serpyanka tape, a primer and self-tapping screws will come in handy in the work. Exterior decoration of gazebos involves the use of a hinged or ventilated facade. Builders include the following advantages of this technology:

- quick installation by hand in any weather;

- high-strength coatings withstand mechanical loads well, exposure to moisture and ultraviolet radiation;

- unlimited choice of materials, due to which you can successfully implement any design solution;

- placement of electrical wiring and a layer of thermal insulation directly under the skin.

The tree for finishing works is supposed to be stored in the warehouse. If this is not possible, you will have to make a canopy for lumber, which is most susceptible to cracking and rotting.

Video "Decorating the gazebo with a crate"

From this video you will learn how to decorate a gazebo with a crate with your own hands.

Materials (edit)

When choosing panels for the interior cladding of structures in the country, the first thing to do is to assess their level of flammability. For example, ondulin ignites much faster than cellular polycarbonate. And natural stone does not form smoke at all, which is especially important for the safe use of gazebos with barbecue.

Non-flammable products belong to the KMO class. This includes most concrete mixes, glass, asbestos cement and bricks. Materials with organic components in the composition contribute to quick installation, but at the same time, they can provoke a fire. Therefore, it is better to choose multi-layer panels covered with a heat-resistant film.

Siding

On the sides, the gazebo is best sheathed with metal siding. Due to the polymer processing of materials, even at the stage of their production, such a finish does not rot, it withstands heat and frost well.

If the owners need high-quality soundproofing of the premises, it is more logical to choose cement siding. It absorbs noise better, is non-flammable and retains its original shape at any temperature. Acrylic panels show great resistance to aggressive environments, and lightweight polyvinyl chloride sheets contribute to natural ventilation of the outer surfaces.

Before installation, it is important to prepare a solid frame from the rails. So that the material does not deteriorate under the layer of vapor barrier and the cladding itself, it should be impregnated with antiseptics.

Corrugated board

The choice of refractory sheets often depends on the height of the corrugation and the shape of the products. For interior decoration, materials with a minimum thickness of 2–4 mm are suitable. If you need to sheathe a round gazebo with a domed roof, you will definitely need thick sheets with a thickness of 8-12 mm. For outdoor use, products of the C21 brand with a higher corrugation height are suitable. The choice of color scheme depends on the ability of the color to visually expand the space, mask scratches and dirt.

In the latter case, it is more profitable to choose brown and gray sheets, and light materials to expand the interior space. The quality of installation largely depends on the correct processing of the corrugated board, so do not forget:

- Thick sheets 55–70 mm thick cannot be cut with a jigsaw. To prevent the metal from deforming, it is recommended to use a circular saw for this purpose.

- The nibbler is better at handling tight turns. As a result, the cut is always straight and the edges are never bent.

- Using a jigsaw, you can improve the shape of the sheet. To increase the resistance of the cut material to corrosion, the edges of the cuts will have to be treated with protective compounds.

Metal grid

If the work needs to be completed in the shortest possible time, it is better to use a plastic mesh. It is attached to the walls with cement mortar. Fasteners are not needed here. When cladding a structure from the street, it is more logical to use a metal base, suitable for securely fixing the plaster layer and strengthening the outer surfaces in general.

The walls of adobe are supposed to be sheathed with a chain-link, with the help of which it is possible to create a high-strength reinforcing layer. Welded mesh is an advantageous option for finishing load-bearing structures. There is no load on the supports here, so we can safely talk about the long-term use of summer extensions. Unlike the chain-link, the welded mesh does not sag, and with timely processing with polymers, it does not deteriorate under the influence of increased moisture.

Block house

Externally, planed boards resemble logs. Their fixation by the thorn-groove method contributes to high-quality cladding of internal surfaces without gaps and cracks. The optimum material thickness is 25 mm, and the width is from 120 mm and more. Before use, the wooden block house is treated with a stain that increases the resistance of products to moisture. Unlike conventional enamel compounds, it penetrates into the deep layers of wood, without disturbing the natural texture of the products.

For outdoor work, metal panels that are resistant to temperature extremes and aggressive environments are more suitable.

Wooden grates

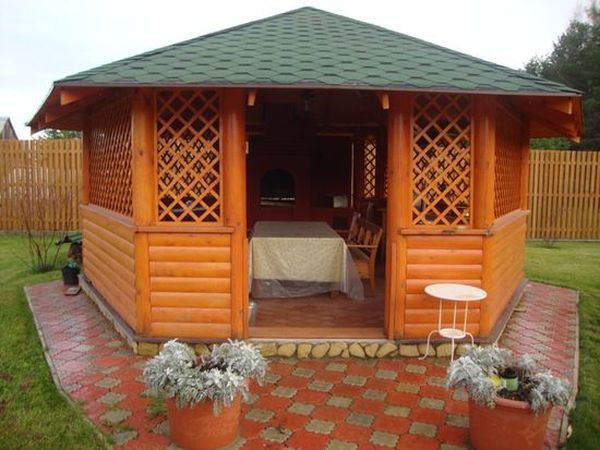

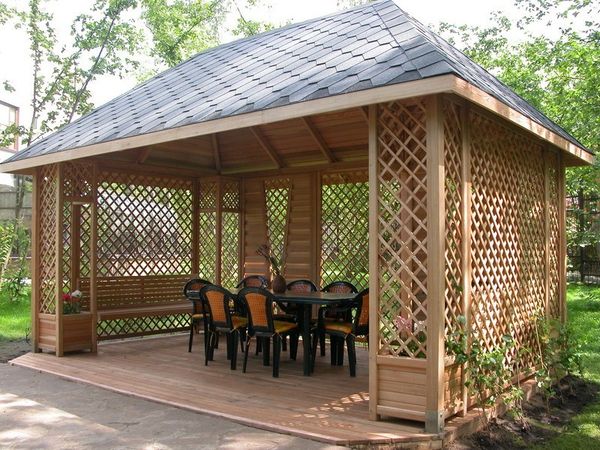

In the presence of lumber, raw materials can be made at home. Crosswise inclined slats are ideal for decorating gazebos without blank walls. In summer, such buildings are always cool, and the smoke from the barbecue goes outside.

For self-assembly of the structure, you will need slats, beams, scissors, nails and varnish. The tree should be treated with protective compounds before and after frame sheathing. The same grill can be installed on the roof of the gazebo. This is a good base for climbing plants.

Polycarbonate

Instead of silicate glass, which creates a greenhouse effect indoors, experts recommend polycarbonate. Monolithic sheets are suitable for finishing any premises. Lightweight honeycomb is the best option for building awnings and arched structures. Bulky buildings are recommended to be sheathed with dense sheets with a thickness of at least 12 mm. In this case, the material lends itself well to processing, does not deform or bend in the wind.

To seal the ends of the products, you will definitely need aluminum profiles.If you use smooth sheets, you will additionally have to make drain holes.

Lining

Extra class products are the best option for interior and exterior decoration of buildings. Materials without a single knot and resin pocket are characterized by a perfectly flat surface, which, in turn, facilitates installation. Sheathing boards are installed with the groove down so that the products do not pick up moisture. Clips will be needed to secure the top edge. Slots can be sealed with planks.

Only wooden lining can be used indoors. Unlike plastic, it retains heat better, and does not emit toxic substances when heated. Primer compounds facilitate fast adhesion of materials. Flame retardants increase the fire resistance of the boards.

A simple do-it-yourself sheathing option

The first step is to prepare the lathing for the installation of the lining. Considering that wooden buildings settle over time, you need to leave a small gap between the ceiling and the floor. You will need self-tapping screws to fix the boards. In this case, the heads of the screws must disappear into the wood. The resulting holes can be masked with putty.

With a minimum thickness of the lining, it is better to use invisible cleats. The first and last cladding elements are fastened with screws. At the end of the work, the walls are varnished.