How to make concrete paths in the country with your own hands: professional advice

Content

Advantages and disadvantages

Making concrete paths has positive and negative sides.

Let's consider the advantages first:

- Ease of arrangement of paths compared to paved materials of similar quality.

- The composition of the concrete solution includes materials that can be purchased at a low price.

- The durability and reliability of the tracks allows you to keep their intended purpose for 20-30 years.

- When using special building additives, the paths become frost-resistant, which increases the service life.

- Moisture-protective properties, which is especially appropriate when the groundwater is close to the ground.

- In the process of pouring concrete, you can embody original ideas for the design of garden paths.

Concrete paths have minor disadvantages:

- High labor intensity of preparatory work, especially when erecting formwork.

- Great dependence on weather conditions when filling tracks. Rainfall, even a few days after the end of the work, can affect the lifespan of the paths.

- When the soil moves, cracks appear on the surface.

- The quality of manual mixing of concrete may not be sufficient. For such work, it will be advisable to use a concrete mixer or other devices.

- The possibility of transferring the finished track is excluded.

Video "DIY concrete path for the garden"

From this video you will learn how to make a quality garden path with your own hands.

Basic building rules

For the reliability of garden paths, it is necessary to observe a clear sequence during construction and carry out the work correctly. Making tracks will require going through the following steps:

- design work;

- territory marking;

- digging up soil;

- installation of formwork;

- the device of the underlying layer;

- manufacturing of reinforcement;

- pouring the solution.

DIY construction

To complete the work, you will need sand, cement, crushed stone and a metal mesh for reinforcement. From the tools you need to prepare:

- several different shovels;

- carpenter's toolbox;

- measuring devices;

- a drill with a special nozzle or concrete mixer;

- trowel, trowel.

Site marking and soil preparation

Using a step-by-step technique, we will consider all stages of the work:

- First of all, you need to complete a project in which the tracks will be drawn and their purpose indicated. For the central passage, the width is assumed to be 1.5–2 m, the rest of the paths will be 0.8–1 m in size. The need for concreting the passages between the beds will be limited to a width of 40–50 cm.

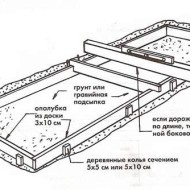

- With the help of a rope and pegs, you need to mark future paths. The width of the outlined lines is made 10-15 cm larger - for the installation of the formwork. All obstacles arising on the way of marking must be rounded, while maintaining the transverse dimension of the path.

- We dig out the soil inside the markings with a shovel - 15 cm deep.If the soil is sandy, then you can dig no deeper than 12 cm.

Formwork

For the manufacture of formwork, you will need boards of small thickness (2–5 cm). The width of these wooden slats should be no less than the height of future paths (15–20 cm). We equip straight sections with the help of such beams, and plywood or other similar flexible material is used for turns.

Adhere to the following algorithm of actions:

- The formwork boards must be knocked down with the help of additional rails, which are located on the outside of the structure.

- Next, the timber is installed along the contours of the track. The height of the upper plane of the battens should be 3-5 cm above the ground and correspond to the project.

- Smooth forms of rounding must be done in place using sand bedding.

- After installing the longitudinal boards, they are fixed with homemade spacers above the level of the paths by 2-3 cm.

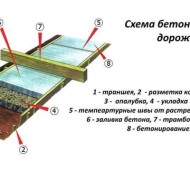

Pillow

The bottom of the trench obtained is covered with agrofibre or roofing material. Then they are covered with fine gravel and sand 3-5 cm thick. The underlying layer must be moistened and tamped. To prevent the track from cracking during seasonal temperature fluctuations, it is necessary to install transverse dividing bars 15 mm thick every 2-3 m. After concreting, these slats are removed.

Reinforcement

Various metal products can be used as a reinforced material: mesh, rods, profiles. This will make it possible to reduce the cost of manufacturing the reinforcement. It is important that everything is tied into one link that resists the rupture of the concrete path. The optimal material for this work would be a welded mesh with square cells 10x10 cm.

You need to do the following:

- Prepare the required amount of reinforcing material.

- Cover the trench with nets or other metal structures at a height of 5–8 cm from the backfill layer. At the edges of the trench, 3-5 cm remains without reinforcement.

- Fasten all metal elements to each other and to the formwork to avoid displacement when pouring concrete.

Fill

After the completion of the preparatory work, we proceed to the final ones:

- Concrete preparation. It is necessary to prepare a mixture of cement, sand and crushed stone in a ratio of 1: 3: 1. Use cement grade M-400, and crushed stone - fine fraction. The specified ratio of the cement composition will allow the garden path to maintain its shape and properties for many years. For pouring the top layer, you can use a ready-made sand concrete mixture. Before purchasing such material, you must carefully read the instructions from the manufacturer, since existing brands have different purposes. The use of special additives will extend the life of the concrete paths.

- After thoroughly mixing the solution to a sour cream consistency, concrete can be poured into the trench. In accordance with the project, the required pouring height is maintained. It is desirable to make the central part of the track 2-3 mm higher. This will avoid the formation of puddles.

- Using a trowel, level the surface of the path in all its sections.

- Allow the solution to harden. To avoid the appearance of cracks during the drying process, the poured areas are covered with polyethylene for several days or more.

Decor

In order for the track to have an attractive appearance, it must be painted or decorated using unnecessary building materials.

Painting can be done while pouring. To do this, use only white cement while stirring the mixture. As a coloring element, it is better to add polyacrylic paints for outdoor use. With this method, the color will be expressive over the entire area of the paths. It is possible to paint the surface after the concrete has dried. In this case, the paint will be affected by temperature changes and precipitation.

Another equally interesting design method is the laying of mosaics from fragments of ceramic tiles, glass or natural stone.To perform such a decor, it is necessary to lay out the patterns using cement mortar on the following days after pouring the concrete.

Another decoration option is applying a color pattern to the surface of the tracks.

To preserve the image for a long time, it is necessary to make shallow grooves the next day after concreting, which will become the contours of the future drawing. Then, after stirring small portions of the solution with the dye, fill these grooves with different colors and press down with a trowel.

Alternative option

If you want to have a relief tropic in the garden, it is made from separate concrete slabs of various shapes. For this, old wooden boxes can be repaired and used as shapes for future rectangular slabs. Or design an original stencil for making a separate section of the track. This stencil can be purchased at a specialty store.

Concrete paths will give the suburban area an elegant look. Their production has a low cost, and the decoration will emphasize the style of the residential building and the buildings surrounding it.