Reliable and stylish metal gazebos: types and construction on your own

Content

Forms and varieties

There are several good reasons for choosing a metal when building a gazebo:

- The soil in the selected area is loose and is in unstable equilibrium.

- From time to time the gazebo will have to be moved to another place.

- Due to the particularly unfavorable climate, the structure requires increased reliability.

- The desire to build a creative structure that needs special strength.

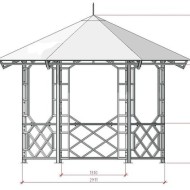

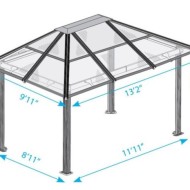

Designers love metal for a reason - with its help, when creating objects, they manage to realize the most daring fantasies. The type and shape of a metal gazebo in the private sector depends only on the preferences of its owners. There are square and round, hexagonal and rectangular, forged, with an arched roof, etc.

Different projects also differ in the assembly method:

- welded structures, all work is done quickly and reliably;

- prefabricated, where the bolts are used as fastening fittings.

By combining both methods, it is possible to organize a gazebo of several modules in the courtyard of the house, which will subsequently allow it to be easily disassembled and transferred to another place or for storage. Like wooden structures, metal gazebos are open or covered with wall structures that protect from wind or snow. Empty openings for the winter can also be covered with polycarbonate sheets or PVC curtains.

Video "DIY metal gazebo"

From this video you will learn how to make a do-it-yourself metal gazebo project.

Which metal is suitable

For the construction of light structures with your own hands, profile pipes of a rectangular or circular cross section are suitable. A wall thickness of 2-3 mm is enough for a gazebo. When choosing a material, you should be guided by practicality. For example, round pipes are cheaper, but welding with them requires special skills, it will be difficult for a beginner to make a strong and beautiful seam.

Another question is whether to prefer steel or stick to aluminum. It all depends on the circumstances:

- steel is cheaper and stronger;

- aluminum is more expensive, but lighter, more convenient to work with, gives the street structure a more colorful look.

It is permissible to build from galvanized metal or painted. Finally, if there are sufficient funds, it is worth building a wrought-iron gazebo, giving it a breathtaking look.

How to build

For a recreation area, experts recommend choosing quiet secluded places with beautiful views of the surrounding nature. But when it comes to metal buildings, technical requirements are also added to the list:

- If the structure is not rigidly attached to the ground, it can be moved or even knocked over by gusts of strong wind. Be sure to consider the wind rose and their strength on the site.

- The ground level should be high so that the floor of the gazebo does not flood on rainy days.

The selected area must be cleaned in preparation for construction. Get rid of debris, dig up roots and shrubs.It is also advisable to remove the top layer of soil, deepening 20 cm deep, which will allow you to get rid of weeds in the future.

The excavated area is covered with a sand pillow, which is tamped with water. On top, you can lay a plastic film or geotextile.

Further actions depend on whether you need a large stationary gazebo or a small portable one. Experts recommend working with unpainted metal so as not to inhale harmful fumes when heating. The material should be painted or varnished at the very end.

With foundation

Stationary buildings require a solid foundation. We'll have to build a columnar foundation, digging holes, constructing a sand cushion in them and pouring concrete into the inserted support posts.

Another option is to concrete the site. On the prepared site:

- formwork is being constructed;

- mesh reinforcement made of wire is laid, for which corrosion is not terrible;

- the pit is poured with concrete, along the way leveling the surface.

In the future, the concrete surface is covered with some kind of floor covering. Paving slabs, natural or artificial stone, wood planks, etc. will do.

To increase reliability, both methods, concreting and columnar foundations, can be combined. For support pillars, profiled pipes are also used.

Without a foundation

For portable gazebos, the foundation is optional. The lower frame is created in advance with special vertically directed supports. With their help, the gazebo is brought and fixed in a prepared area, covered with paving slabs or natural stone. True, for mobility, the dimensions of such a structure should be small.

Wall materials

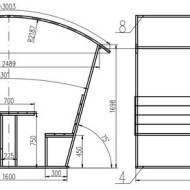

The frame of the building is made by welding or bolting the parts according to the selected drawing. Here is a step-by-step instruction:

- First, the support posts are scalded with rows of veins (a belt of shaped pipes) located at different heights from each other. The first row of lower jumpers is fixed at a height of 80 cm from the ground, the next row is 20 cm higher.

- The frame of the frame is welded. Jumpers are attached to the ends of the support posts according to the drawing. The height of all elements must be the same.

- The upper harness is mounted - pipes 40x25 mm are placed on the supports and welded.

- The finished frame is primed, the primer is allowed to dry, and then painted.

It is recommended to carry out welding work together: one master will cook, the other will check the evenness of the entire structure.

When constructing a closed gazebo, the side of the frame is also covered. For this purpose, the same polycarbonate is suitable, although you can simply decorate the "walls" with metal bars or specially welded homemade openwork structures.

Roof

The easiest way to make a gable roof is as follows.

The frame is first welded on the ground, then lifted and fixed on the upper harness. At the end, the frame is covered with roofing material: polycarbonate, roofing profiled sheet, metal tiles. Most often, polycarbonate sheets are used, they can be given a curved shape, getting picturesque arched structures complete with curved profile pipes.

It is better to fix this material with thermal washers. For this:

- A sheet of material is laid, leveled.

- With a drill for metal at the point of the fastener, a through hole is made through the material and the metal.

- The sheet is fixed with thermal washers.

- The ends of cellular polycarbonate are insulated with special protective tapes.

The floor for a stationary gazebo is made last:

- Transverse logs are attached to the lower junction with a step of 50 cm.

- Holes are drilled in the logs with a step of 30 cm.

- With the help of self-tapping screws, boards are mounted as a floor covering.

It is recommended that the prepared boards first be subjected to special processing. To do this, the wood is impregnated with wood stain, sanded.It is necessary to paint and varnish the boards only after the completion of all work.

Decor

Although the frame of the structure is made of metal, wooden planks are quite suitable for decoration. For their installation, wooden bars with pre-made holes are attached to the horizontal pipes of the frame, and strips are attached on top of the bars.

You can decorate the interior in different ways. Flowers are the first thing that comes to mind when decorating a garden gazebo. Climbing plants, such as grapes, are suitable for the entire structure. Fresh flowers in bright pots, hung on the walls, also look beautiful.

There are other possibilities as well. Forged jewelry looks good. Textiles are a beautiful and practical decor option. Light curtains will not only decorate the walls, but also create good protection from the wind.

Since the metal is not afraid of fire, you can install a portable barbecue in the built gazebo or even build a full-fledged barbecue oven from bricks, turning the gazebo into a summer kitchen.

Having made a choice in favor of metal as a building material, you will not go wrong. Gazebos with a metal frame are reliable, serve for a long time, delighting their owners with a beautiful openwork look.