We make a do-it-yourself corn plow

general description

A corn plow is such a useful device with an electric motor, which helps the owner to do a large amount of work without physical fatigue and spend a minimum of time on it. It can be of two types: large, into which a bucket is poured or even more ears for processing, or small, designed for one ear.The first, with a capacity of 1 bag, is capable of peeling it in 3 minutes, that is, in an hour such a mechanical assistant is able to process half a ton of corn.

A small cultivator is not designed for such volumes, it copes with only one ear at a time - it is held by hand, inserted into the hole of the unit alternately, first with one end, then with the other end. Of course, you can't peel half a ton of the harvest - either the engine will burn out, or the person will be tortured to stand for an infinitely long time, repeating the same action. But if the harvest is only a couple of bags, then it's still hard to do it with your hands. How to husk corn is easier and easier - no need to think long.

Each unit usually has a hole or even a chute for removing the cleaned grain, but the cobs from the large drum fall out to the other side, for which there is a separate hole, or they are simply removed by hand.

Principle of operation

Each such electromechanical assistant is equipped with a motor powered by electricity. The motor of a large unit rotates a disc with non-sharp teeth, most often they are welded in the form of round growths up to 8 mm high. In the same disk, round holes are made for the grains, a kind of a sieve with growths is obtained.

During operation, the disc rotates rapidly (up to 50 revolutions per minute), the cobs, crushed by their mass, beat and cling to the teeth, the grains fly out. The grains are poured out through the holes, as well as the gaps between the disc and the hopper into the lower compartment, from which, without acceleration, simply obeying the force of gravity, they fall into the substituted container through a special chute. The same force of gravity and centrifugal force causes new ears to fall onto the cleaning disc, and already cleaned, lighter ones - to rise up. When the grain stops pouring, it means that only empty, peeled ears are left in the hopper. Some structures are equipped with a special hole, from where they fall out by themselves.

How to hull corn with a small machine? The principle is the same, only instead of a rotating disc, it is equipped with a pipe with teeth bent inward, the grains cling to them, which makes them say goodbye to the head of cabbage. They also crumble down, and an empty ear remains in the hands of a person.

The principle of operation of the devices is the same, only the arrangement of the cleaning element in the large apparatus is horizontal, and in the small one it is vertical.

The corn plow is not a very complex mechanism, it does not consume too much energy - it all depends on the power of the motor and the amount of work. But it is indispensable for processing the harvest of those farms where corn is harvested specifically for feeding livestock.

How to make

Such devices of different capacities and different volumes can be bought. They are on sale, their advertisements are found on the Internet. But most craftsmen prefer to make them themselves. A do-it-yourself corn plow is made from improvised means. Old washing machines with a round body, used gas cylinders, motors from some old appliances, even just a drill can come in handy.

In order to make such a machine, you must first of all decide on the volume of the processed crop, then find it on the Internet, ask somewhere on the forum or draw a drawing yourself.

According to the drawing, you need to pick up all the components, tools and fasteners that you may need. Only then can you start the manufacturing process itself.

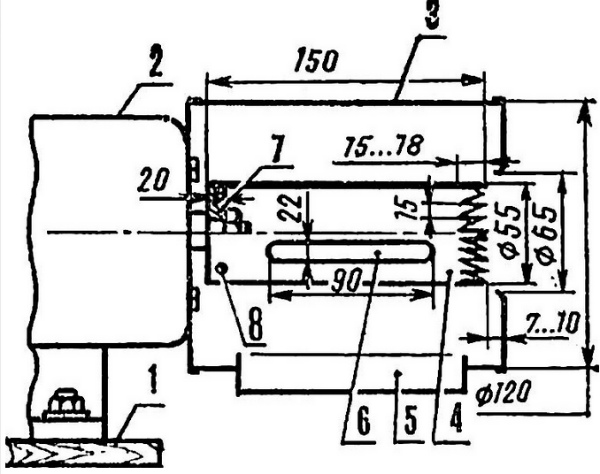

Each unit must have a solid, stable base, a hopper made of a washing machine or a cylinder, an aluminum pipe - a kind of capacious cylinder, is attached to it. A magnetic starter with an engine on / off toggle switch is placed on its wall. The grain separator is connected to the tray flap.

For the loss of grains, a disk is made with holes with a diameter of 14 mm and welded on rounded teeth with a height of 8 mm. Perpendicular to the disk from the bottom, 2 plates of 2 cm are welded, and a rubber scraper is attached to them, which will guide the falling out grains. The flange is pressed onto the motor shaft, and a toothed disk is attached to it. On one side of the hopper, a hole is made at the bottom, a tray is attached along which the grains fall out. On the other hand, a hole is made a little higher through which the spent cobs are selected. For him, you need to make a flap door and fix it so that it does not open spontaneously during operation.

From above, the hopper needs to be closed, which means that they make such a cover that is easy to lift, but which will not open while the engine is running.

Video "Do-it-yourself corn plow"

Take advantage of the idea of assembling a stubble cultivator for quality separation of corn kernels from the cob. Details in the video.